You may fill out barge inspection check list effortlessly with our online PDF editor. To make our editor better and easier to use, we consistently work on new features, with our users' suggestions in mind. Getting underway is simple! All you have to do is stick to these simple steps directly below:

Step 1: Open the PDF file inside our editor by pressing the "Get Form Button" at the top of this page.

Step 2: With the help of our online PDF editing tool, it is easy to accomplish more than just complete blank fields. Express yourself and make your docs appear faultless with customized textual content added in, or modify the file's original content to excellence - all that comes with the capability to add stunning pictures and sign the PDF off.

Pay attention while filling out this pdf. Ensure that all necessary fields are filled in correctly.

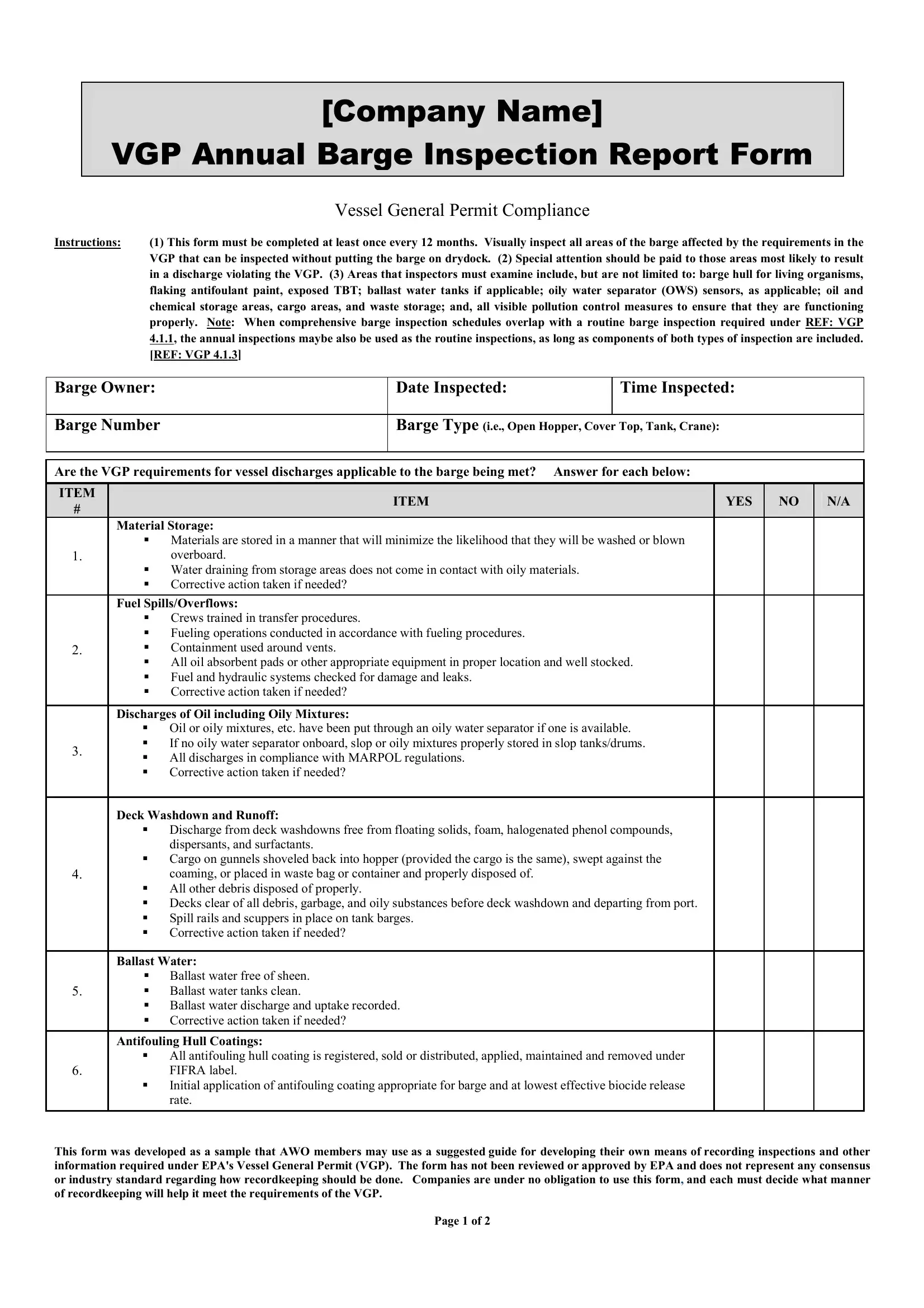

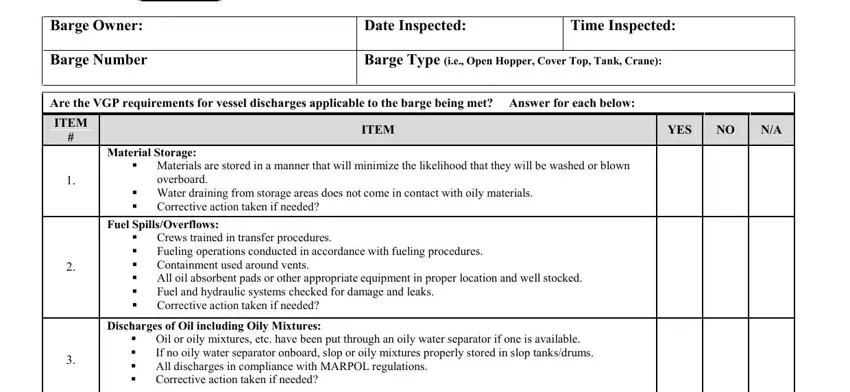

1. It is critical to complete the barge inspection check list accurately, thus take care while filling in the parts including all these blanks:

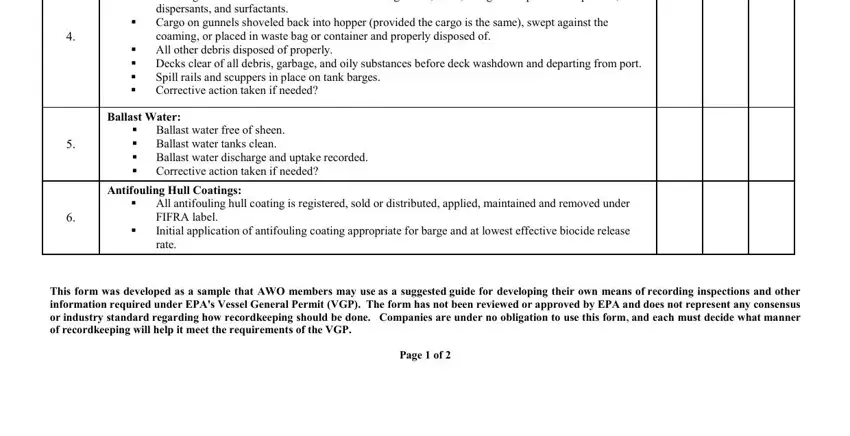

2. Right after the prior selection of fields is filled out, go to enter the applicable details in all these: Discharge from deck washdowns free, Ballast Water, Ballast water free of sheen, Antifouling Hull Coatings, All antifouling hull coating is, This form was developed as a, and Page of .

Regarding Discharge from deck washdowns free and Ballast water free of sheen, be sure that you get them right in this current part. These could be the key ones in this document.

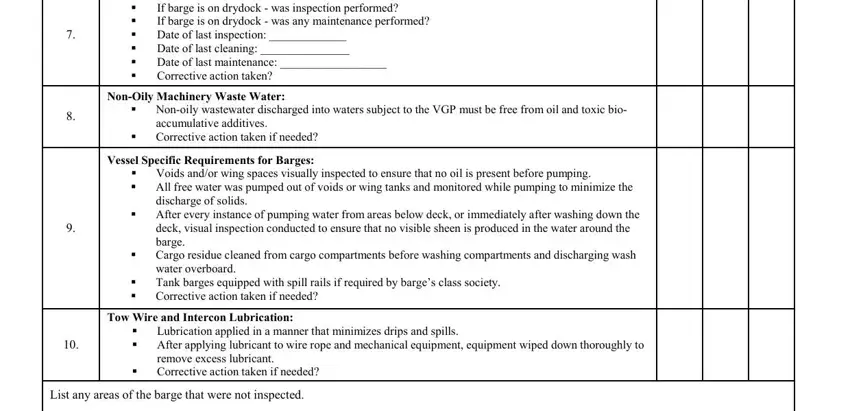

3. This next part will be about Cathodic Protection, If barge is on drydock was, NonOily Machinery Waste Water, Nonoily wastewater discharged into, Vessel Specific Requirements for, Voids andor wing spaces visually, Tow Wire and Intercon Lubrication, Lubrication applied in a manner, and List any areas of the barge that - type in all these empty form fields.

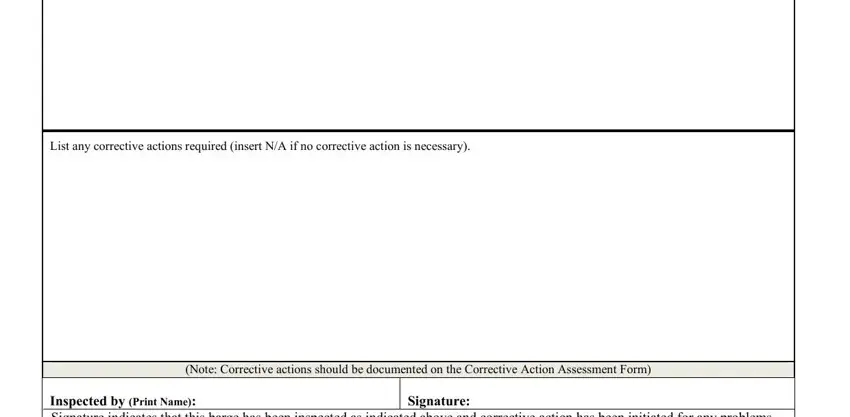

4. You're ready to complete this fourth section! In this case you will get all these List any corrective actions, Note Corrective actions should be, Inspected by Print Name Signature, and Signature blanks to fill in.

Step 3: Immediately after taking another look at the form fields you've filled in, click "Done" and you are done and dusted! Right after starting afree trial account at FormsPal, you will be able to download barge inspection check list or email it directly. The file will also be available from your personal cabinet with your every change. FormsPal is devoted to the privacy of our users; we ensure that all personal information put into our tool is secure.