prevention plan checklist template can be completed online very easily. Just use FormsPal PDF editor to get the job done promptly. Our editor is constantly developing to provide the very best user experience possible, and that is due to our dedication to continuous development and listening closely to user feedback. To begin your journey, consider these simple steps:

Step 1: Simply click on the "Get Form Button" in the top section of this webpage to launch our pdf file editor. This way, you'll find all that is required to fill out your document.

Step 2: This editor allows you to customize almost all PDF forms in many different ways. Change it with any text, correct what is already in the document, and place in a signature - all readily available!

As for the blank fields of this precise PDF, this is what you should do:

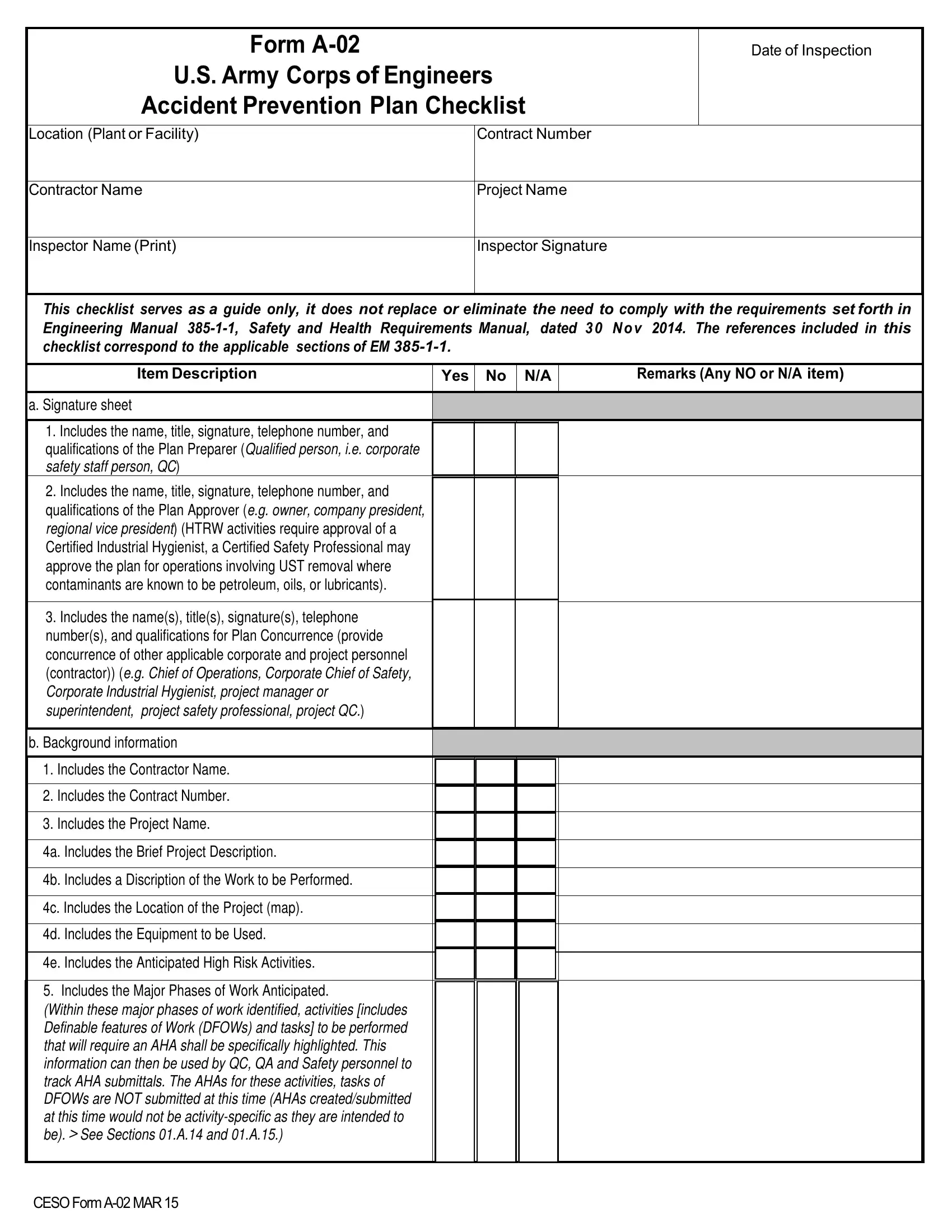

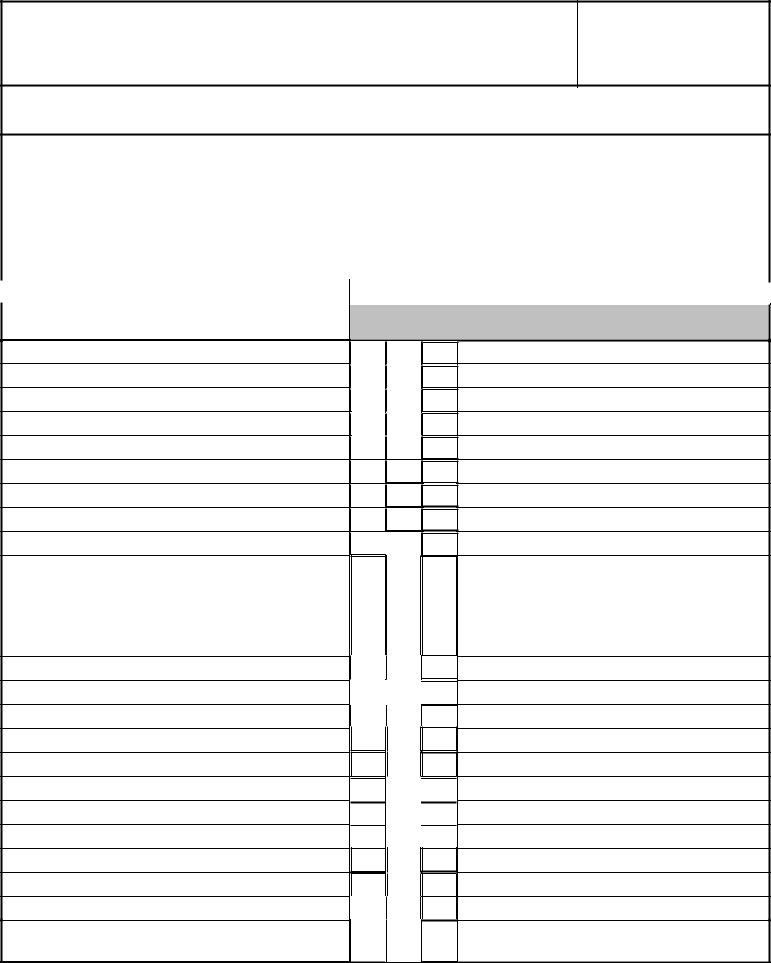

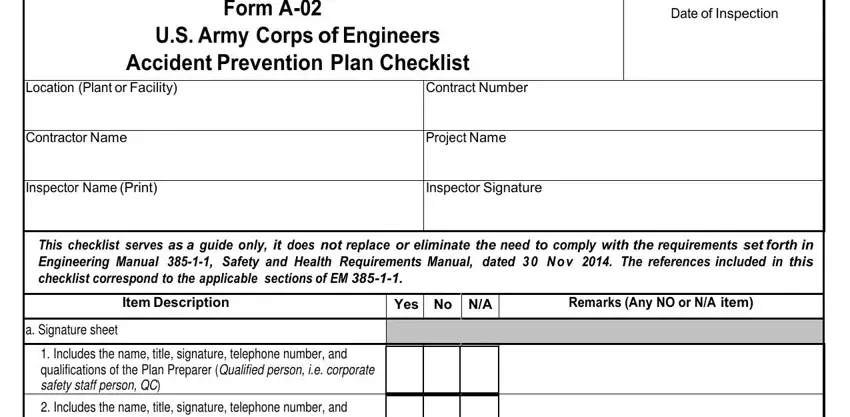

1. When filling in the prevention plan checklist template, make certain to complete all of the important blanks within the relevant area. This will help hasten the work, making it possible for your information to be processed without delay and correctly.

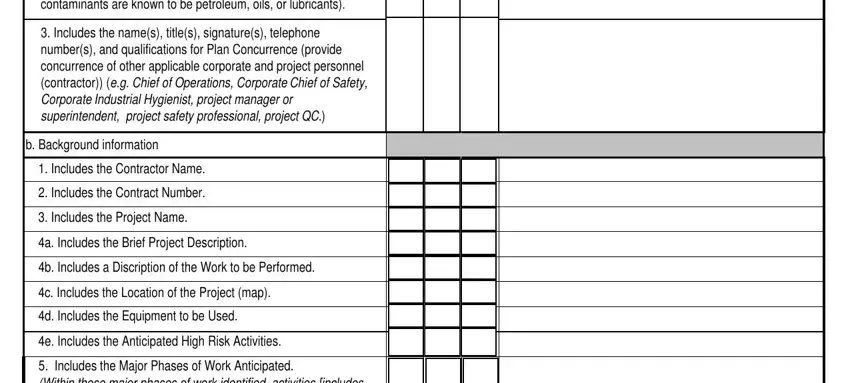

2. After the previous part is done, you'll want to insert the essential specifics in Includes the name title signature, Includes the names titles, b Background information, Includes the Contractor Name, Includes the Contract Number, Includes the Project Name, a Includes the Brief Project, b Includes a Discription of the, c Includes the Location of the, d Includes the Equipment to be Used, e Includes the Anticipated High, and Includes the Major Phases of Work so you're able to move on further.

Always be very attentive when filling out b Includes a Discription of the and d Includes the Equipment to be Used, because this is the section where many people make some mistakes.

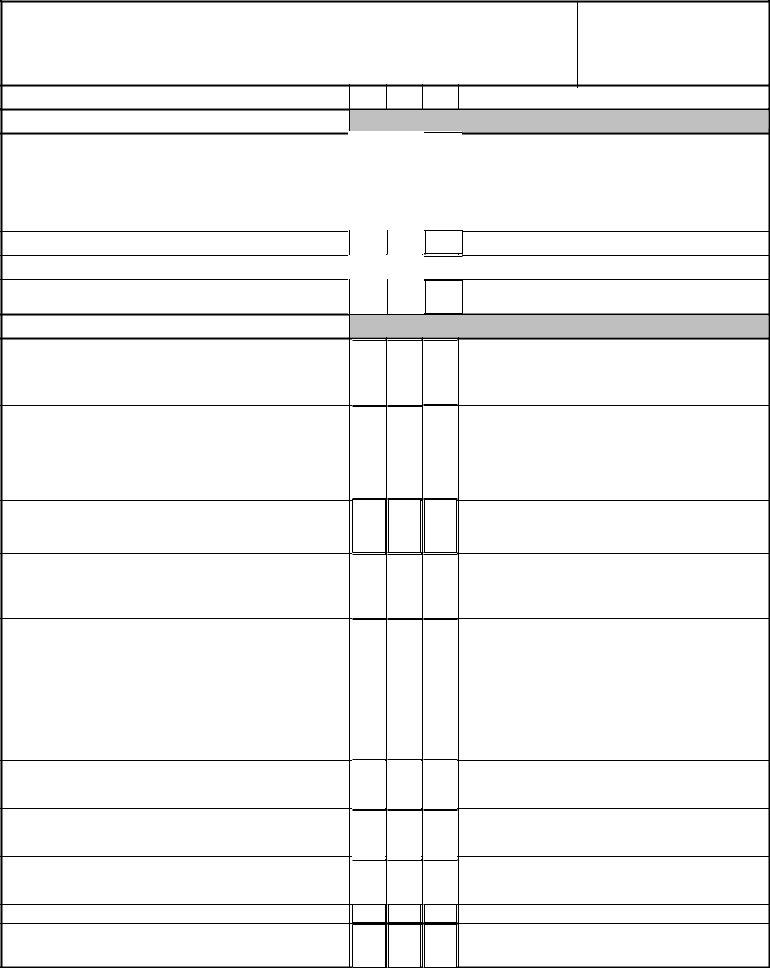

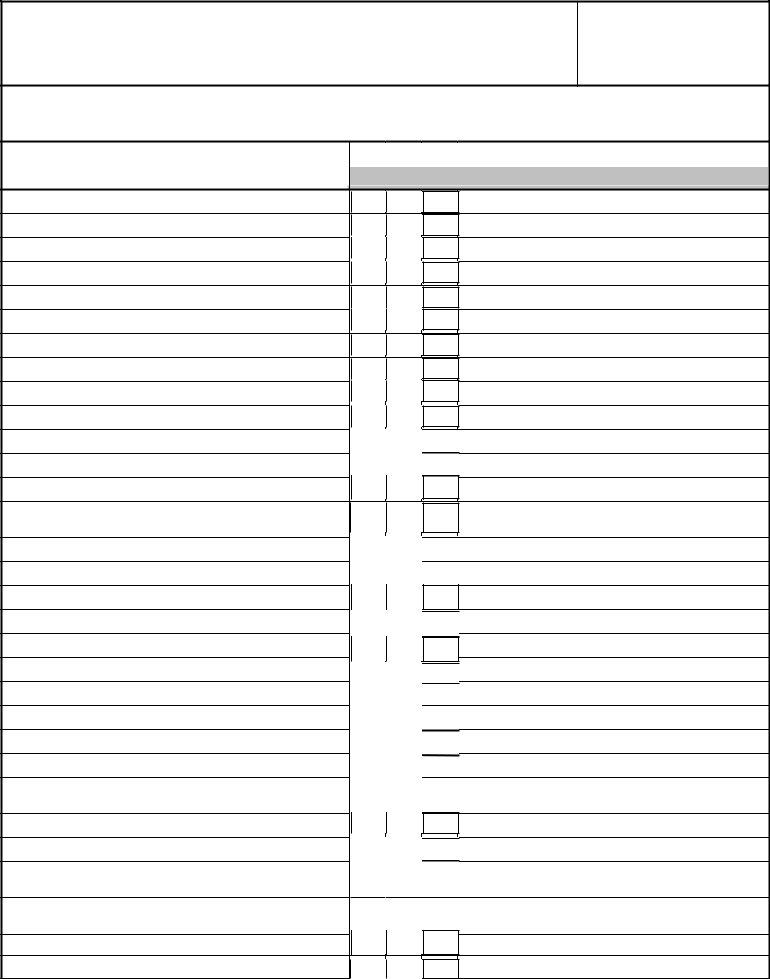

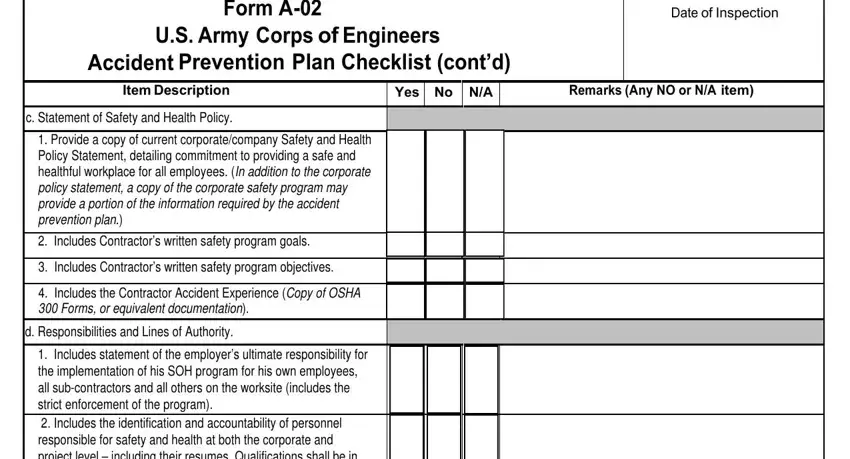

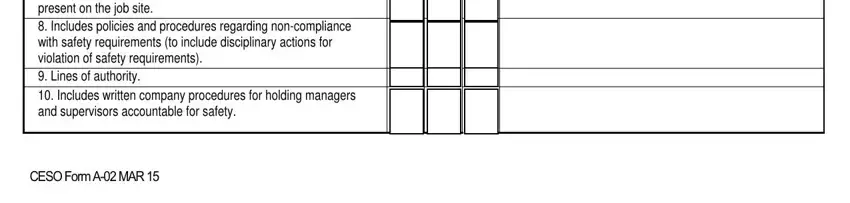

3. Throughout this step, check out Form A, Date of Inspection, US Army Corps of Engineers, Accident Prevention Plan Checklist, Item Description, Yes No NA, Remarks Any NO or NA item, c Statement of Safety and Health, Provide a copy of current, Includes Contractors written, Includes Contractors written, Includes the Contractor Accident, d Responsibilities and Lines of, and Includes statement of the. Each one of these will need to be filled out with utmost precision.

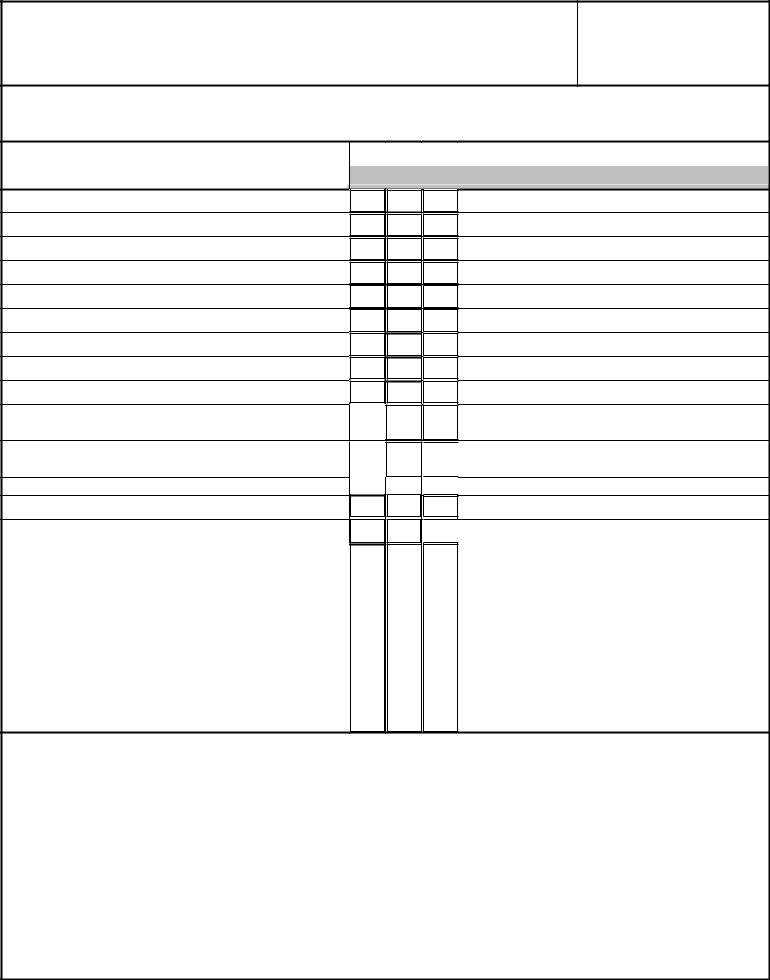

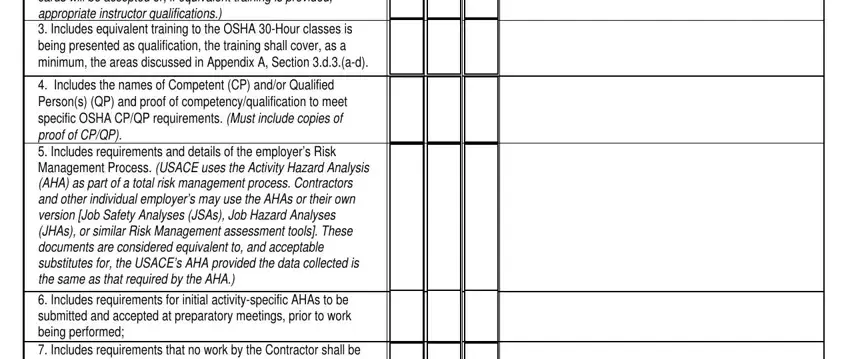

4. The subsequent section arrives with these particular blanks to fill out: Includes statement of the, Includes the names of Competent, and Includes requirements for initial.

5. To wrap up your document, this final subsection involves a couple of extra blank fields. Filling out Includes requirements for initial, and CESO Form A MAR is going to finalize everything and you will be done in no time!

Step 3: Go through all the details you have entered into the form fields and click the "Done" button. Right after registering afree trial account at FormsPal, you will be able to download prevention plan checklist template or email it without delay. The PDF document will also be at your disposal via your personal cabinet with your modifications. At FormsPal, we do our utmost to be certain that your details are kept secure.