By using the online editor for PDFs by FormsPal, you're able to complete or modify cf1r add here and now. In order to make our editor better and simpler to use, we consistently work on new features, with our users' suggestions in mind. Here's what you would have to do to get going:

Step 1: Access the PDF doc inside our tool by clicking the "Get Form Button" at the top of this webpage.

Step 2: The tool grants the opportunity to change PDF forms in many different ways. Modify it by writing customized text, adjust what's originally in the document, and include a signature - all within the reach of several mouse clicks!

Completing this form usually requires thoroughness. Make certain all required blank fields are completed correctly.

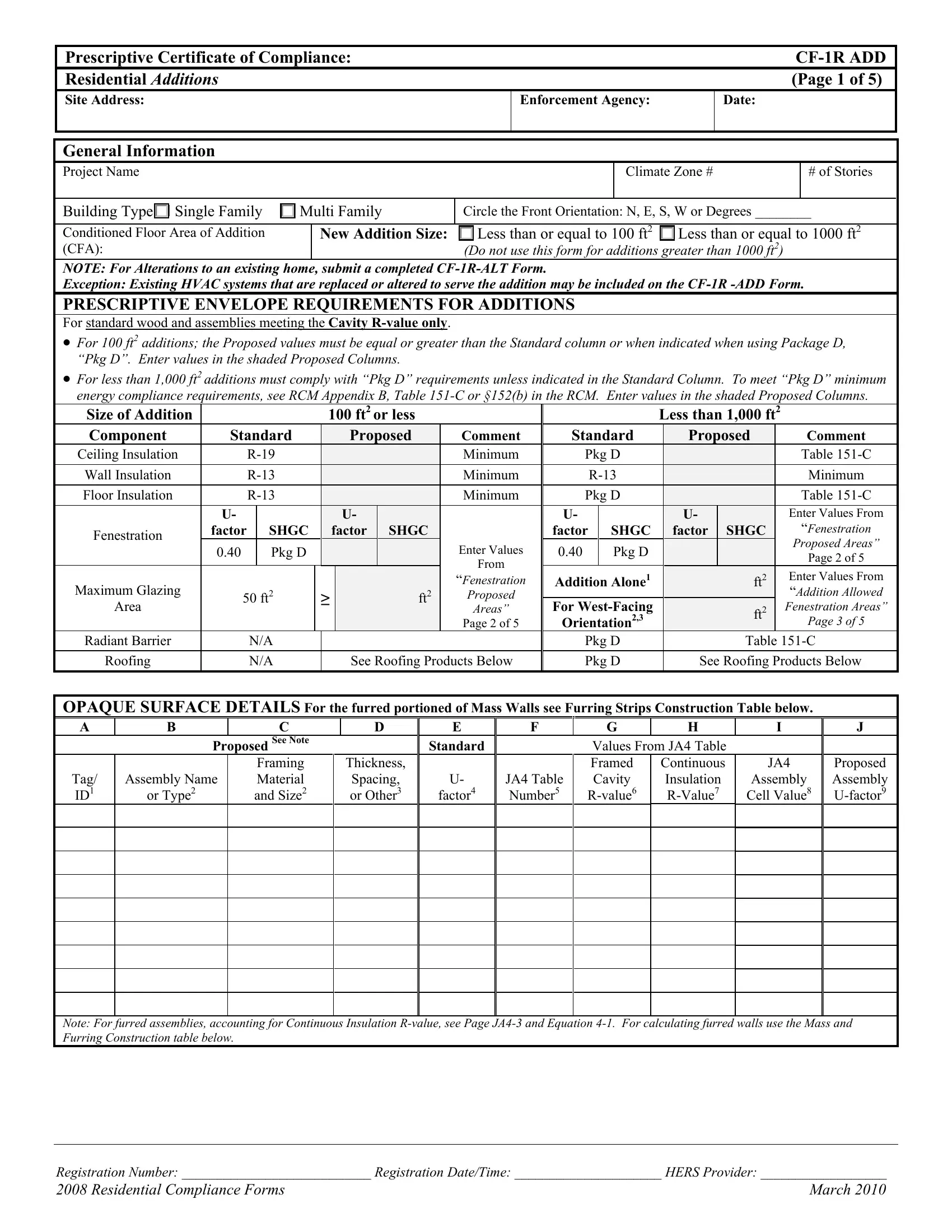

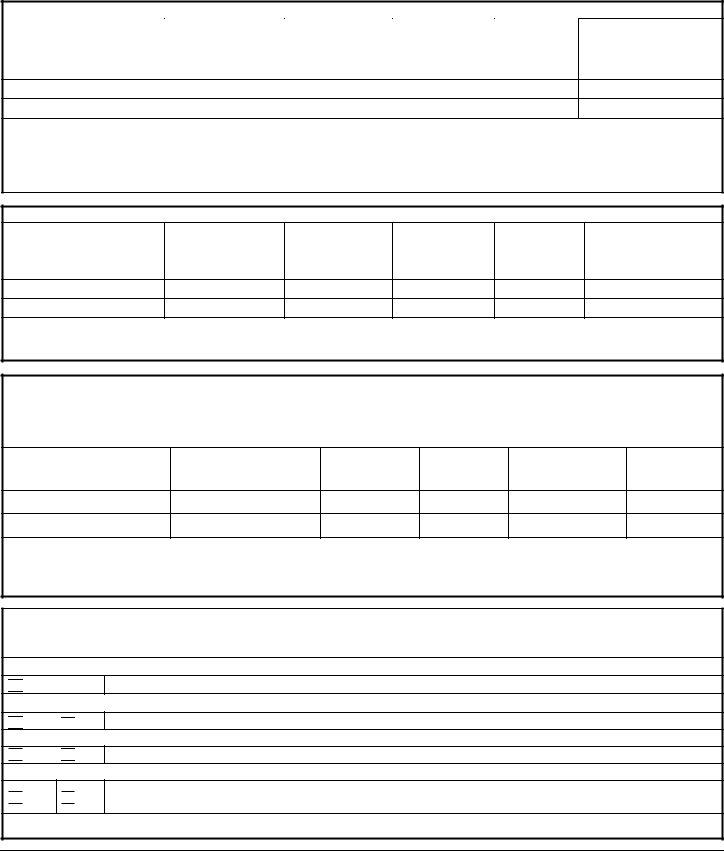

1. To start off, while filling out the cf1r add, beging with the area that has the following blanks:

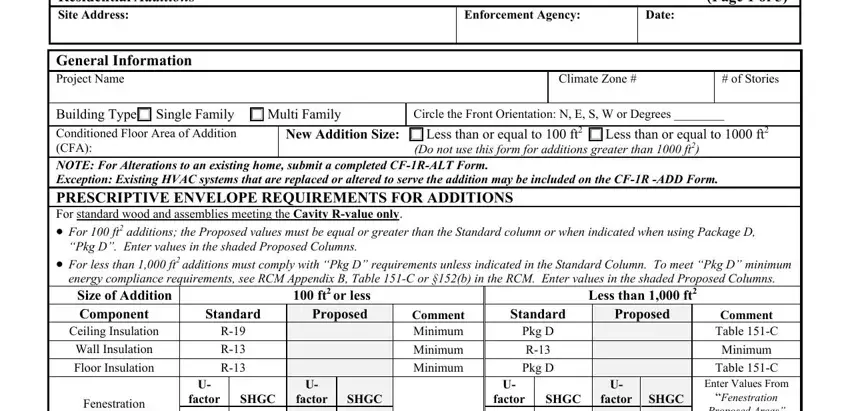

2. After completing the previous section, head on to the subsequent stage and fill in the necessary particulars in all these blank fields - Pkg D, Maximum Glazing, Area, Radiant Barrier, Roofing, factor, SHGC Pkg D, Proposed Areas, Page of, Enter Values, From, Fenestration, Addition Alone, Proposed, and Areas.

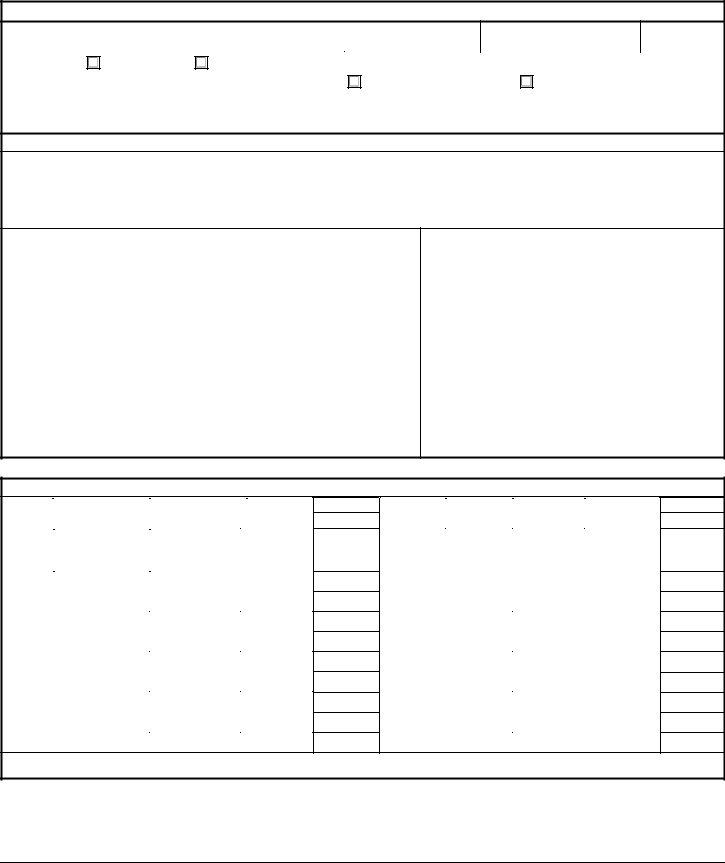

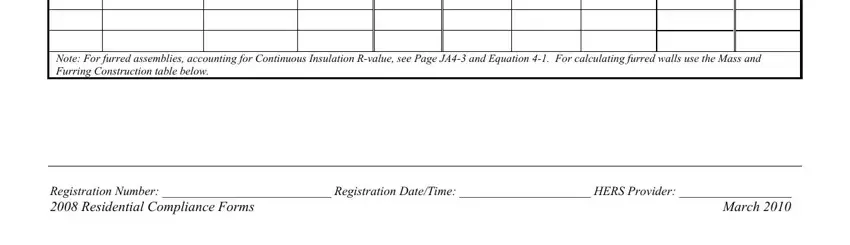

3. Through this step, examine Note For furred assemblies, and Registration Number Registration. All these will need to be filled in with highest accuracy.

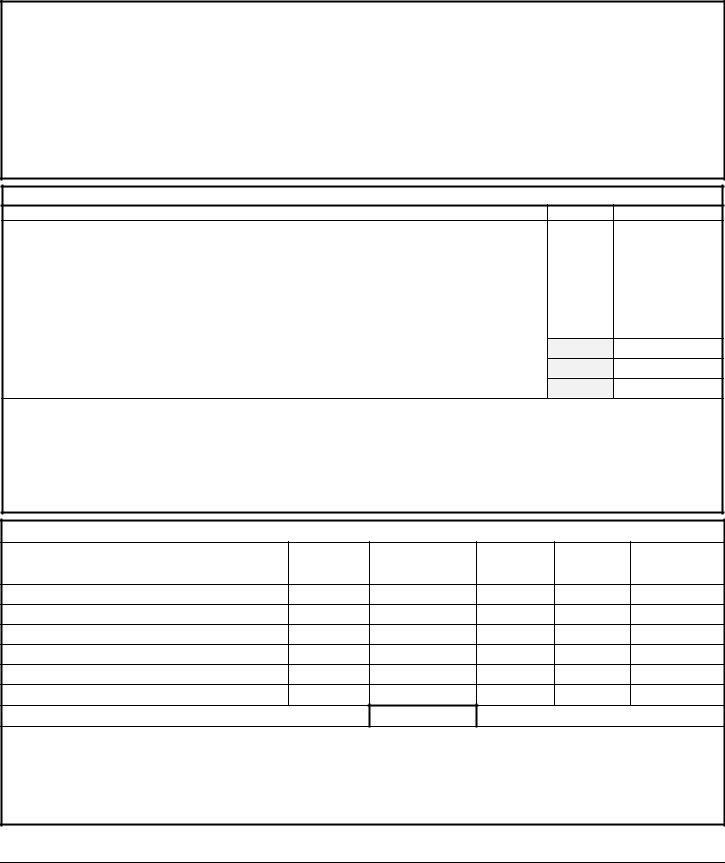

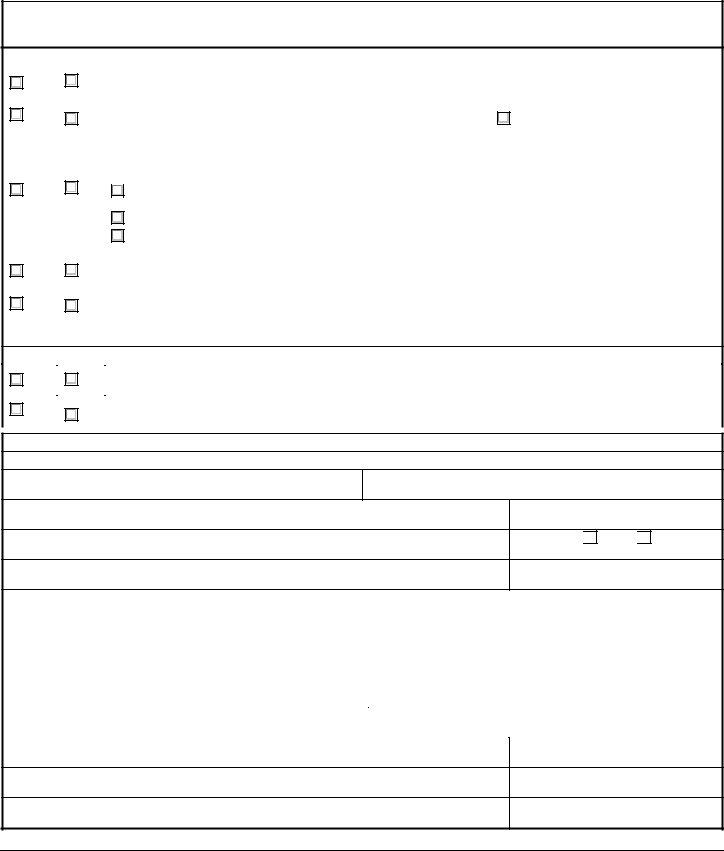

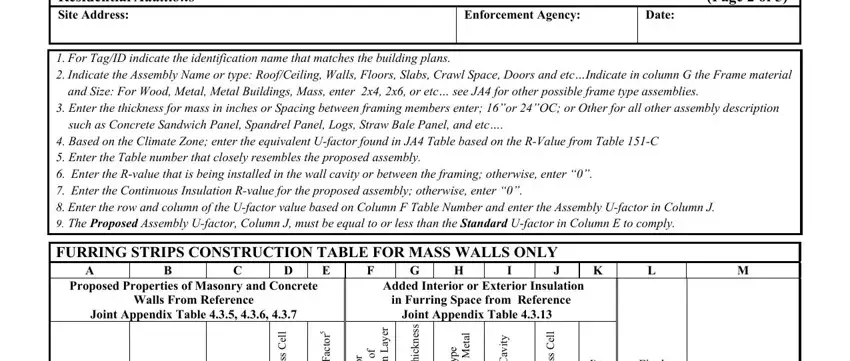

4. The subsequent section requires your details in the subsequent parts: Prescriptive Certificate of, Enforcement Agency, Date, For TagID indicate the, and Size For Wood Metal Metal, Enter the thickness for mass in, such as Concrete Sandwich Panel, Based on the Climate Zone enter, FURRING STRIPS CONSTRUCTION TABLE, Proposed Properties of Masonry and, Added Interior or Exterior, Walls From Reference, Joint Appendix Table, in Furring Space from Reference, and Joint Appendix Table. Ensure that you enter all required details to go forward.

It's easy to make errors while filling out your Proposed Properties of Masonry and, hence make sure that you go through it again before you'll submit it.

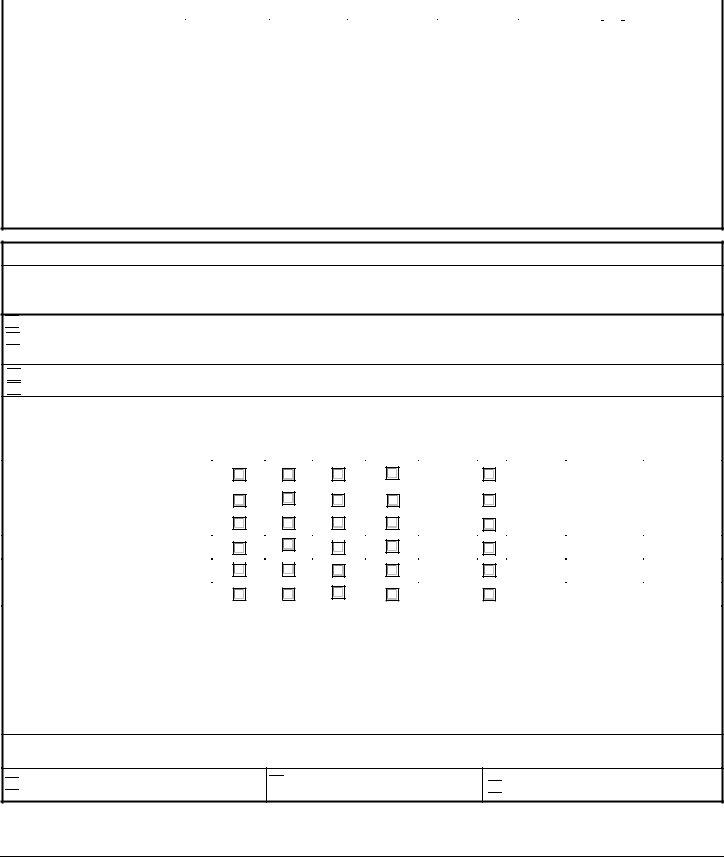

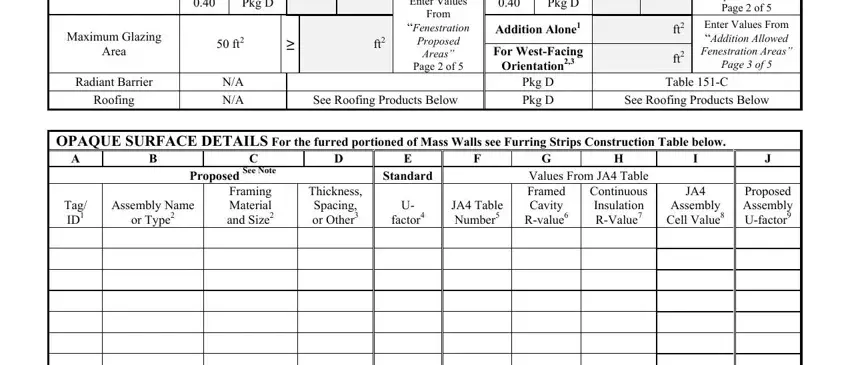

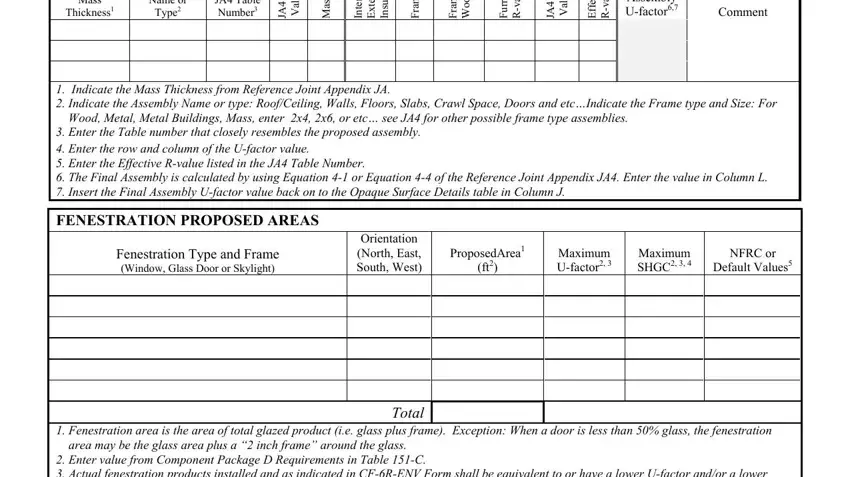

5. To conclude your document, the final section includes a few additional blanks. Entering Mass, Thickness, Assembly Name or, Type, JA Table Number J A, r o t c a F U s s a, e u l a V, r e y a L n o i t a l u s n I, r o i r e t x E, r o r o i r e t n I, s s e n k c i h T e m a r F, e p y T e m a r F, d o o W, y t i v a C g n i r r u F, and e u l a v will wrap up the process and you can be done very fast!

Step 3: Prior to finalizing the form, check that form fields have been filled out the right way. As soon as you determine that it's correct, click “Done." Grab your cf1r add as soon as you sign up for a 7-day free trial. Immediately use the form within your personal account page, with any modifications and changes conveniently kept! When you work with FormsPal, it is simple to complete forms without having to be concerned about personal information breaches or data entries getting shared. Our secure software ensures that your private details are maintained safely.