The Crops Record form serves as a comprehensive tool for farmers specializing in combinable crops, ensuring adherence to the standards set by the Assured Combinable Crops Scheme. It spans a wide array of categories, from general records, such as contact information and certifications for spray operators, to more specific areas like grain storage, the application of chemicals, fertilizers, and treatments, as well as granular dust handling. This form also covers equipment related to grain handling and the use of moisture meters and temperature probes, underscoring the importance of maintaining grain quality post-harvest. Additionally, it includes sections on rodent control, detailed field records, emergency contact numbers alongside a contingency plan, pesticide inventories, and complaint logs. The inclusion of self-assessments for secure storage of fertilizer, grain store risk assessments, and mycotoxin risk assessments highlight the regulatory compliance aspects. An appendix provides guidance on calculating buffer zones for spray operations, ensuring environmental protection. This array of sections demonstrates a thorough approach to farm management, emphasizing safety, traceability, and quality assurance in crop production. The form not only serves as a record-keeping mechanism but also as a guideline for best practices in crop management and sustainability.

| Question | Answer |

|---|---|

| Form Name | Crops Record Form |

| Form Length | 34 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 8 min 30 sec |

| Other names | crops record book, crop recording software, crops record, sa global combinal crops |

Combinable Crops Farm Record Book

Combinable Crops Record Book

Harvest 2009

SAI Global FABBL Assured Combinable Crops Scheme

CONTENTS

Section 1 – General Records |

3 |

|

|

|

|

Section 2 – Grain Storage |

4 |

|

|

|

|

Section 3 – Chemical, Fertilizer and Granular Dust Application Equipment |

10 |

|

|

|

|

Section 4 – Grain Handling Equipment |

10 |

|

|

|

|

Section 5 – Moisture Meters/Temperature Probes |

10 |

|

|

|

|

Section 6 – Rodent Control |

11 |

|

|

|

|

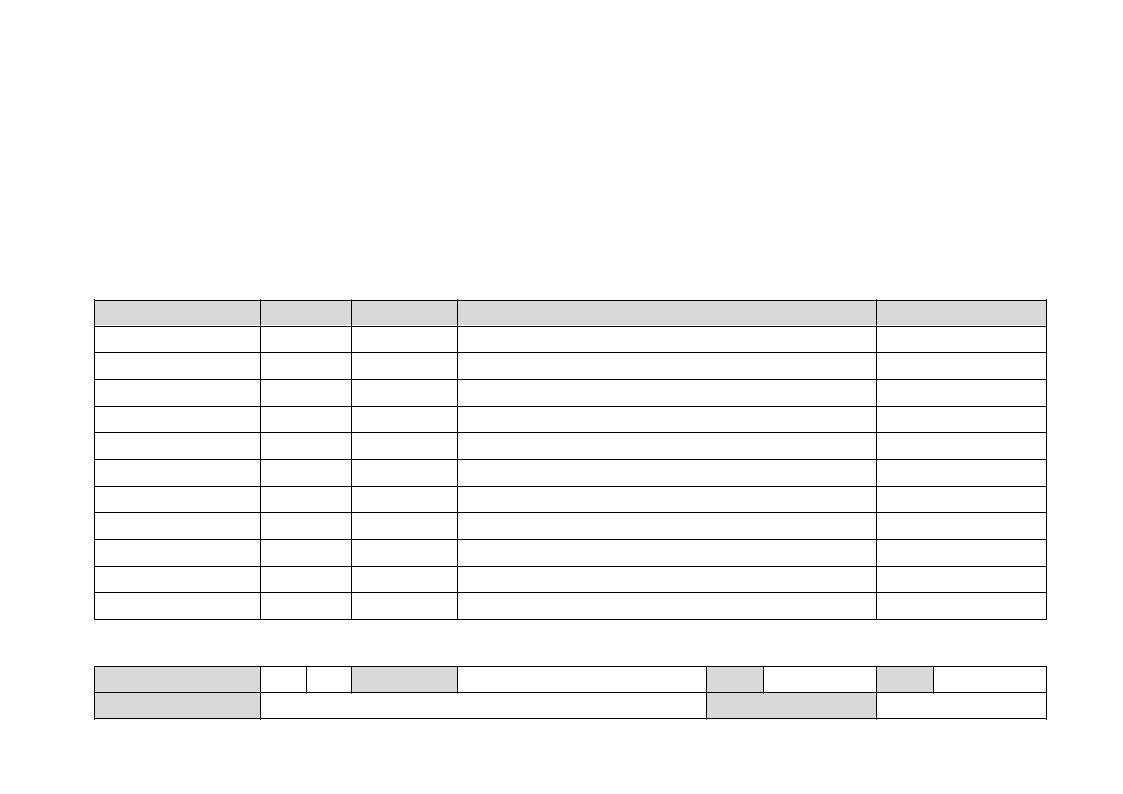

Section 7 – Field Record |

12 |

|

|

|

|

Section 8 – Emergency Phone Numbers and Contingency Plan |

24 |

|

|

|

|

Section 9 – Pesticide Inventory |

25 |

|

|

|

|

Section 10 |

– Complaints Record |

27 |

|

|

|

Section 11 |

– Secure Storage of Fertilizer Self Assessment |

28 |

|

|

|

Section 12 |

– Grain Store Risk Assessment |

29 |

|

|

|

Section 13 |

– HGCA Mycotoxin Risk Assessment |

30 |

|

|

|

Appendix: How to calculate the LERAP buffer zone applicable |

|

|

|

to the proposed spray operation |

32 |

|

|

|

2

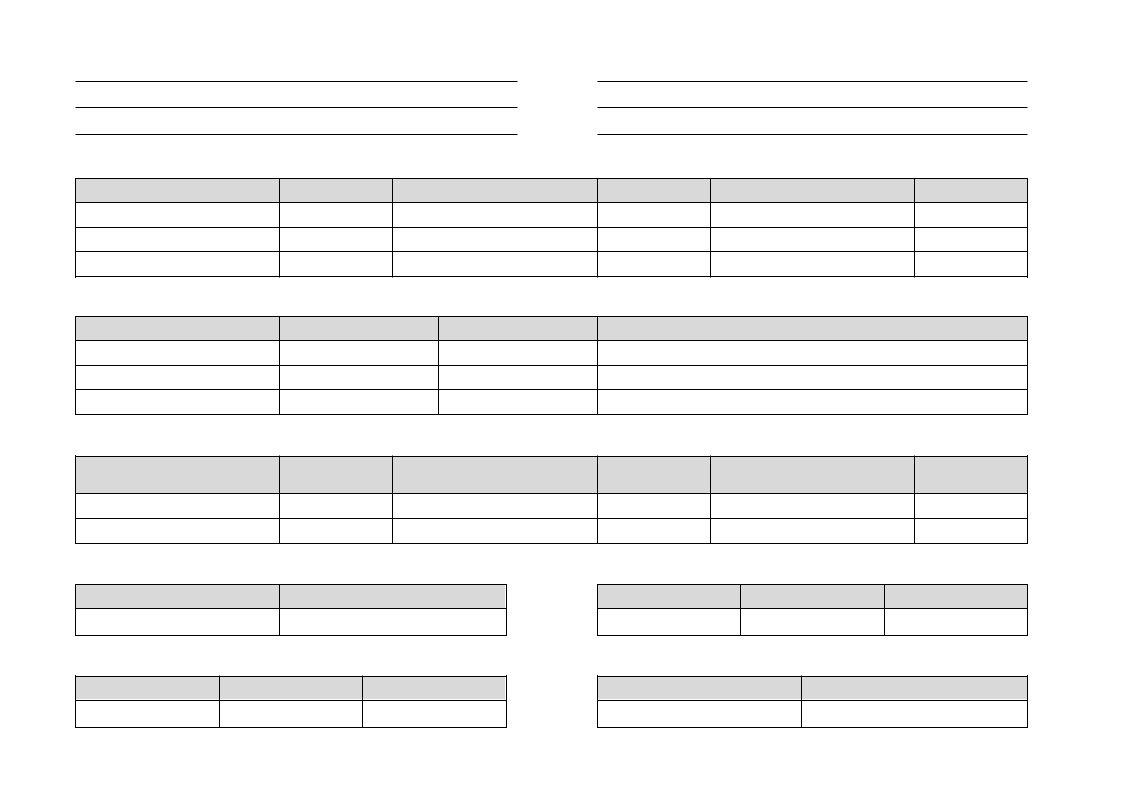

SECTION 1: GENERAL RECORDS

Name

Address

FABBL Membership No.

Tel No. |

Fax No. |

SPRAYER / SEED TREATMENT / GRANULAR DUST OPERATORS CERTIFICATES OF COMPETENCE

Name

Certificate No.

Name

Certificate No.

Name

Certificate No.

CONSULTANTS BASIS / FACTS DETAILS

Name

Basis No.

Facts No.

Address

CONTRACTORS DETAILS

Name

Certificate

details

Name

Certificate

details

Name

Certificate

details

SPRAY OPERATORS NRoSO DETAILS

Name |

NRoSO No. |

CONTRACTORS SPRAYER NSTS DETAILS

Make |

NSTS No. |

Date last test |

SPRAYER NSTS DETAILS

Make |

NSTS No. |

Date last test |

LOCAL BEEKEEPERS LIAISON OFFICER

Name |

Tel No. |

3

SECTION 2: GRAIN STORAGE

Store Name/No. |

|

|

|

|

|

Bin/Bulk/Bay |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Cleaning |

Yes □ |

No □ |

Product used |

|

|

|

Rate |

|

Date |

|

|

|

|

|

|

|

|

|

|

|

|

Insect baiting |

Yes □ |

No □ |

Product used |

|

|

|

Rate |

|

Date |

|

|

|

|

|

|

|

|

|

|

|

|

Insecticide treatment |

Yes □ |

No □ |

Product used |

|

|

|

Rate |

|

Date |

|

|

|

|

|

|

|

|

|

|

|

|

CROP INVENTORY

Date in

FieldÕs ID

Tonnes

Variety/Varieties

Date out

Pesticide treatment Yes □ No □ Product used |

Rate |

Date |

Reason for treatment |

OperatorÕs name |

|

4