PVNTMED can be filled out without difficulty. Simply use FormsPal PDF tool to accomplish the job promptly. FormsPal development team is constantly working to expand the editor and help it become much faster for users with its handy features. Make the most of today's revolutionary opportunities, and discover a heap of unique experiences! To get started on your journey, go through these simple steps:

Step 1: Open the PDF file in our tool by hitting the "Get Form Button" in the top part of this webpage.

Step 2: The tool will give you the opportunity to modify most PDF documents in a variety of ways. Modify it with your own text, adjust existing content, and add a signature - all manageable in minutes!

This PDF form will involve some specific details; to guarantee accuracy, take the time to take into account the following guidelines:

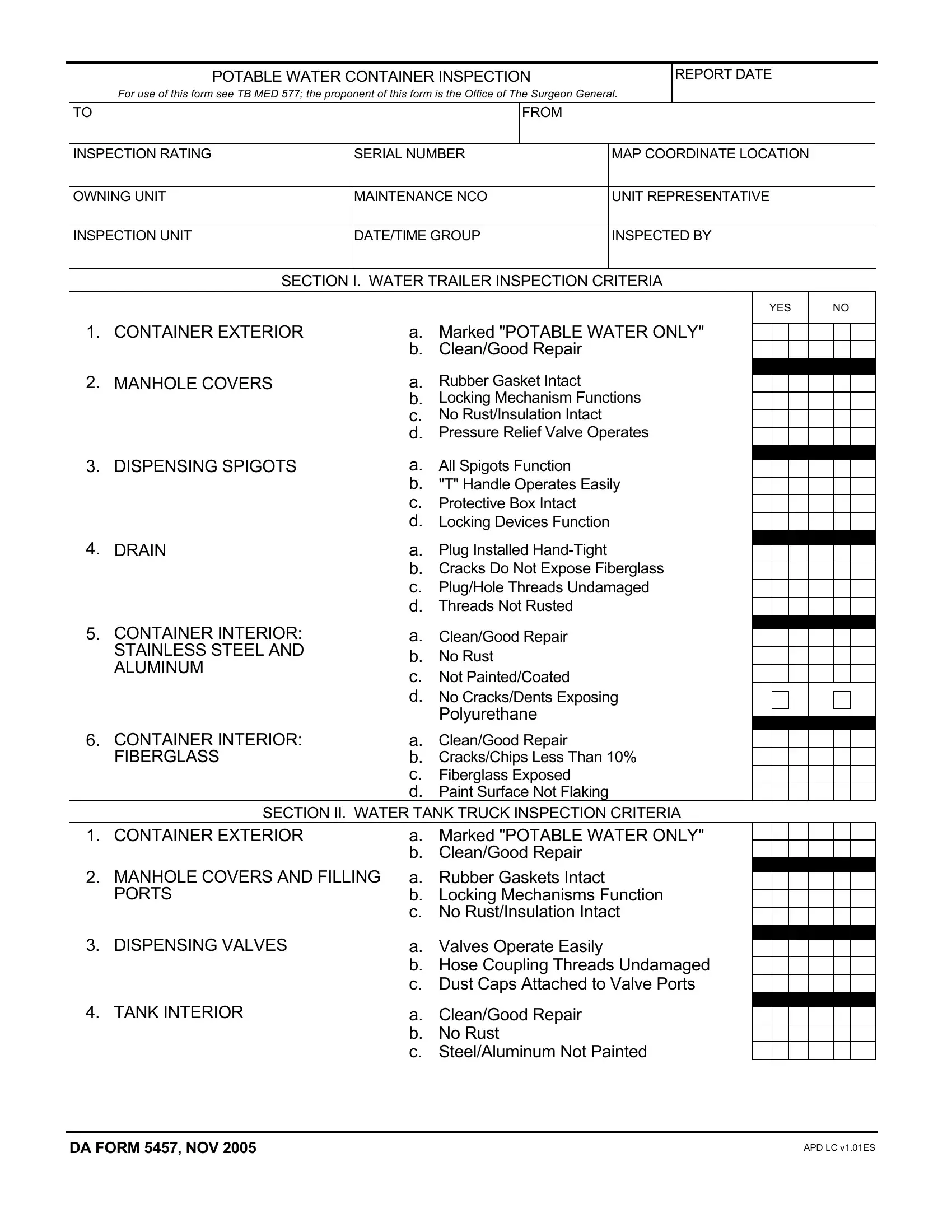

1. Start completing the PVNTMED with a group of essential blanks. Note all the necessary information and be sure there is nothing missed!

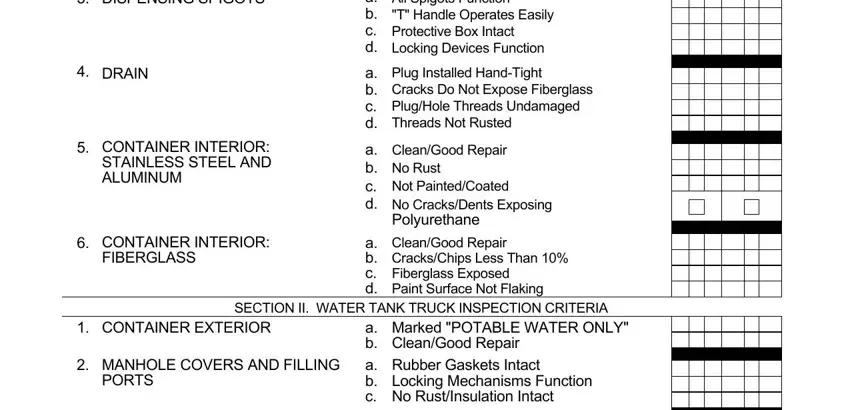

2. Once your current task is complete, take the next step – fill out all of these fields - DISPENSING SPIGOTS, DRAIN, CONTAINER INTERIOR STAINLESS STEEL, CONTAINER INTERIOR FIBERGLASS, a b c d, a b c d, a b c d, a b c d, All Spigots Function T Handle, Plug Installed HandTight Cracks Do, CleanGood Repair No Rust Not, CleanGood Repair CracksChips Less, SECTION II WATER TANK TRUCK, CONTAINER EXTERIOR, and MANHOLE COVERS AND FILLING PORTS with their corresponding information. Make sure to double check that everything has been entered correctly before continuing!

As for a b c d and CONTAINER INTERIOR FIBERGLASS, be certain that you take a second look in this section. The two of these are thought to be the most important fields in this page.

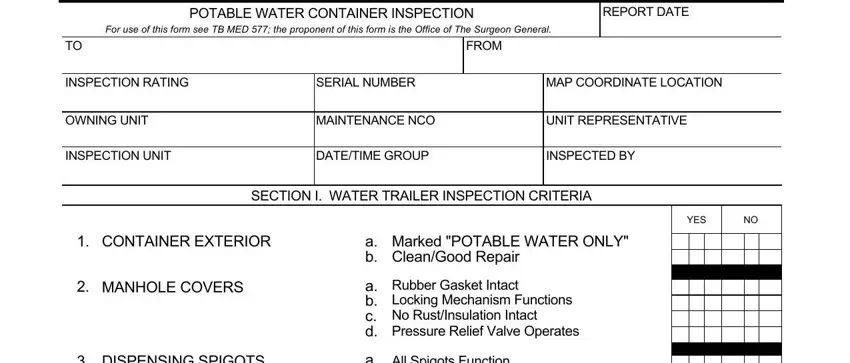

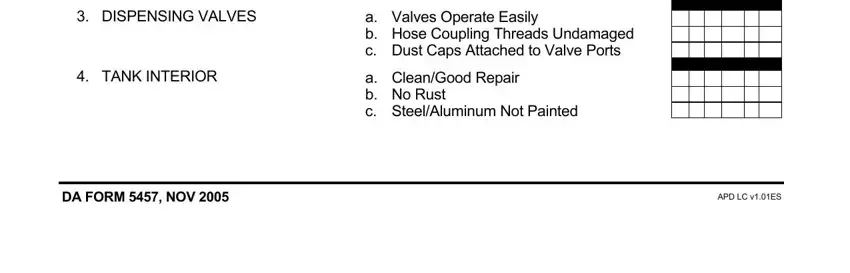

3. This step is generally easy - fill out all the empty fields in DISPENSING VALVES, TANK INTERIOR, a b c, a b c, Valves Operate Easily Hose, CleanGood Repair No Rust, DA FORM NOV, and APD LC vES in order to complete this part.

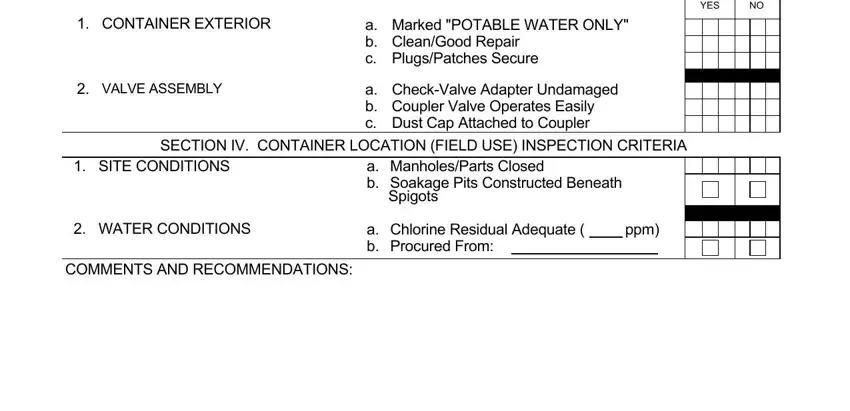

4. This specific part comes next with the next few empty form fields to fill out: YES, CONTAINER EXTERIOR, VALVE ASSEMBLY, a b c, a b c, Marked POTABLE WATER ONLY, CheckValve Adapter Undamaged, SECTION IV CONTAINER LOCATION, SITE CONDITIONS, a b, ManholesParts Closed Soakage Pits, WATER CONDITIONS, a b, Chlorine Residual Adequate, and ppm.

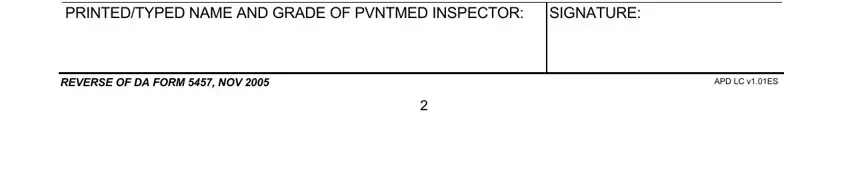

5. The pdf needs to be finalized by filling in this area. Here you will find a comprehensive set of blank fields that must be filled out with specific details to allow your document submission to be faultless: PRINTEDTYPED NAME AND GRADE OF, SIGNATURE, REVERSE OF DA FORM NOV, and APD LC vES.

Step 3: Immediately after taking one more look at your fields and details, click "Done" and you're done and dusted! Right after registering afree trial account with us, it will be possible to download PVNTMED or email it right off. The PDF will also be readily accessible via your personal account page with all your modifications. FormsPal guarantees your information privacy by having a secure system that in no way saves or distributes any sort of private information used in the file. Rest assured knowing your paperwork are kept safe any time you work with our service!