We've applied the endeavours of the best computer programmers to build the PDF editor you are about to work with. Our application will help you create the aws form n 2 document easily and don’t waste precious time. What you need to undertake is keep up with these easy-to-follow recommendations.

Step 1: Select the button "Get form here" to access it.

Step 2: Right now, you can start modifying your aws form n 2. The multifunctional toolbar is available to you - add, eliminate, adjust, highlight, and carry out various other commands with the text in the document.

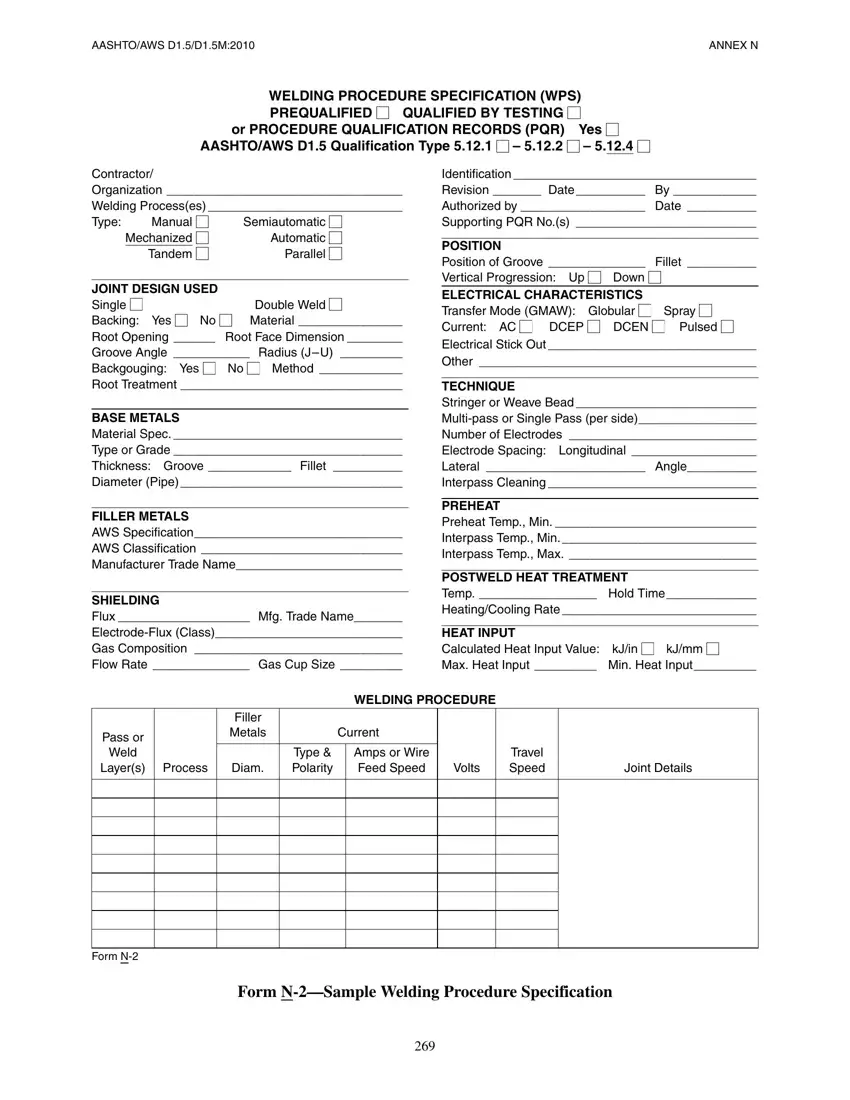

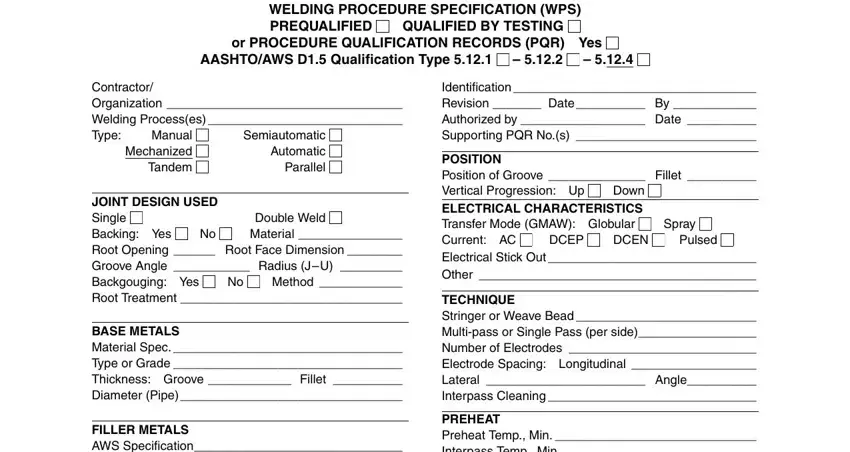

Make sure you enter the next information to prepare the aws form n 2 PDF:

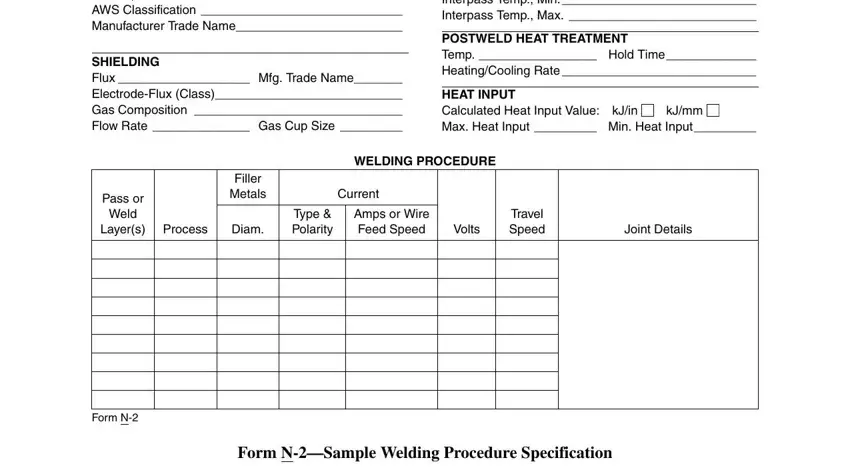

In the FILLER METALS AWS Specification, SHIELDING Flux Mfg Trade Name, PREHEAT Preheat Temp Min, POSTWELD HEAT TREATMENT Temp Hold, HEAT INPUT Calculated Heat Input, kJmm, WELDING PROCEDURE, Filler Metals, Current, Process, Diam, Type Polarity, Amps or Wire Feed Speed, Volts, and Travel Speed area, note down your data.

Step 3: Hit the button "Done". Your PDF file is available to be transferred. You can easily obtain it to your pc or email it.

Step 4: Make sure you prevent forthcoming complications by making at least two duplicates of your document.