Creating documents along with our PDF editor is simpler than most things. To edit official the form, there is little you should do - basically keep to the actions listed below:

Step 1: Step one should be to click the orange "Get Form Now" button.

Step 2: At this point, you are able to update the official. This multifunctional toolbar will let you add, get rid of, modify, highlight, and also do several other commands to the words and phrases and fields inside the form.

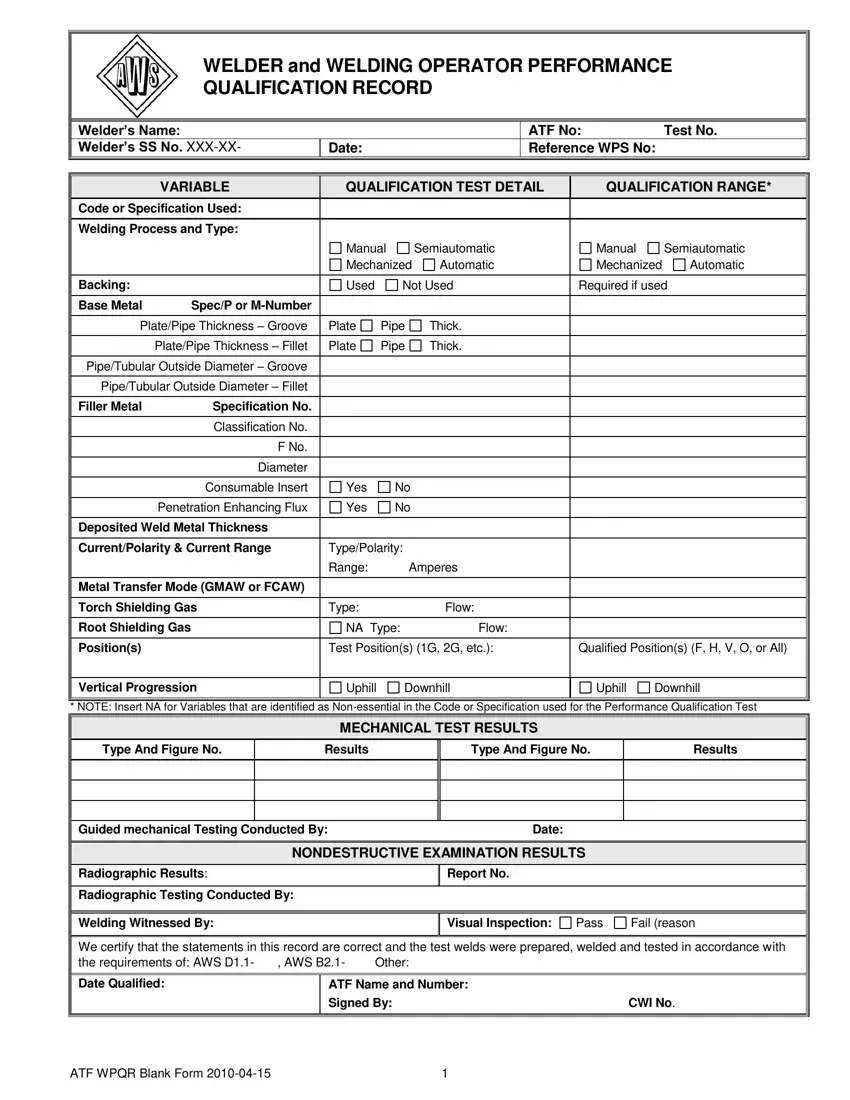

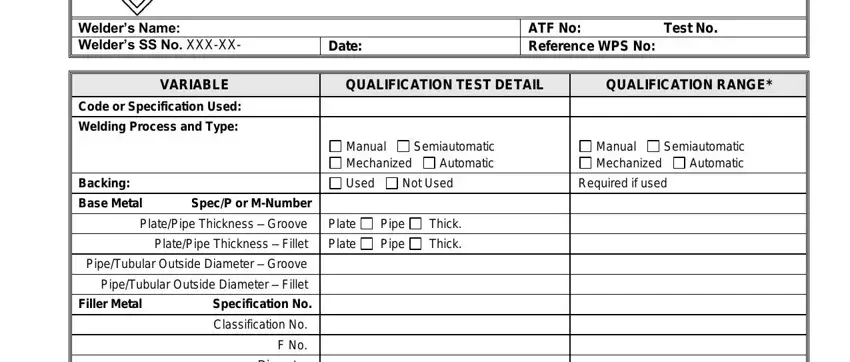

Complete the following sections to complete the template:

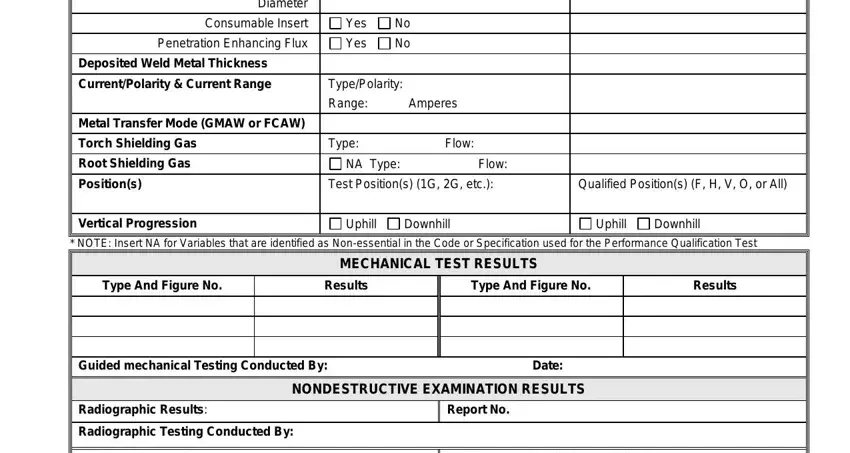

Complete the Diameter, Consumable Insert, Penetration Enhancing Flux, Yes, Yes, Deposited Weld Metal Thickness, CurrentPolarity Current Range, TypePolarity, Range Amperes, Metal Transfer Mode GMAW or FCAW, Torch Shielding Gas, Root Shielding Gas, Positions, Type, and Flow field using the information demanded by the software.

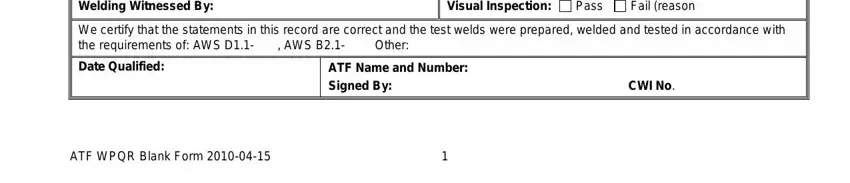

You have to include particular information within the space Welding Witnessed By, Visual Inspection, Pass, Fail reason, We certify that the statements in, Date Qualified, ATF Name and Number Signed By, CWI No, and ATF WPQR Blank Form.

Step 3: As soon as you've clicked the Done button, your document should be readily available transfer to any kind of electronic device or email address you specify.

Step 4: Be certain to remain away from possible problems by making around a couple of copies of the document.