The Food Protection Training Manual, revised edition 2013, published by the New York City Department of Health and Mental Hygiene, plays a crucial role in ensuring that food service operators and their supervisors are well-equipped with the necessary knowledge to maintain high standards of food safety. This comprehensive guide covers a broad range of topics essential for the prevention of public health hazards in food establishments. These topics include an introduction to food safety, the importance of receiving and storing food correctly, understanding hazards that can affect our health, recognizing and managing food allergies, the microbiology of foods, common foodborne illnesses, and the significance of personal hygiene in food preparation. Additionally, the manual discusses crucial operational processes such as cooking, hot holding, cooling, and reheating of food, along with cleaning and sanitizing practices. It delves into the HACCP Food Protection System, pest control measures, plumbing requirements, operating a temporary food service establishment, and the necessary postings required by law. The manual also provides insight into reduced oxygen packaging, local laws, extracts from the NYC Health Code, food defense strategies, trans fat regulation, and workplace safety and health. The inclusion of the Form 198E Food Establishment Inspection Report, along with quizzes, worksheets, and essential contact numbers, makes this manual an indispensable resource for ensuring food safety and compliance with local health regulations. Aimed at fostering a comprehensive understanding of food protection, this manual serves as a key reference for the Food Protection Course offered by the Health Academy, further enabling food service supervisors to effectively oversee food preparation activities and uphold public health standards.

| Question | Answer |

|---|---|

| Form Name | Food Protection Training Manual |

| Form Length | 97 pages |

| Fillable? | No |

| Fillable fields | 0 |

| Avg. time to fill out | 24 min 15 sec |

| Other names | food protection course study guide, nyc food protection course final exam questions, nyc food protection final exam answers pdf, nyc food handlers final exam answers |

C I T Y O F N E W Y O R K

TABLE OF CONTENTS

Introduction 1

Introduction to Food Safety 2

Receiving Foods 4

Storage of Food 8

Hazards to Our Health 11

Food Allergies 12

Microbiology of Foods 13

Common Foodborne Illnesses 18

Personal Hygiene 22

Food Preparation 24

Cooking, Hot Holding,

Cooling & Reheating 25

Cleaning and Sanitizing 31

HACCP Food Protection System 35

Pest Control 38

Plumbing 48

Operating a Temporary Food

Service Establishment 51

Required Postings 53

Reduced Oxygen Packaging 55

Local Laws 56

NYC Health Code Extracts 58

Food Defense Strategies 60

Trans Fat 62

Workplace Safety and Health 66

Form 198E Food Establishment

Inspection Report 69

Quizzes 75

Numbers to Remember 79

Work Sheets 83

foDEPARTMENT OF HEALTH & MENTALdHYGIENE

P R O T E C T I O N

T R A I N I N G

M A N U A L

R E V I S E D E D I T I O N , 2 0 1 3

fo d P R O T E C T I O N T R A I N I N G M A N U A L

d P R O T E C T I O N T R A I N I N G M A N U A L

If you have questions or com- ments regarding this manual,

please call the Health Academy at

(917)

If you wish to contact:

OATH – HEALTH TRIBUNAL 66 John Street, 11th Floor

NY, NY 10038

☎(212)

BUREAU OF FOOD SAFETY &

COMMUNITY SANITATION

125 Worth Street, 9th & 10th Floors Box

☎(212)

☎(212)

CITYWIDE

LICENSING CENTER

42Broadway NY, NY 10004

☎(212)

HEALTH ACADEMY 413 East 120 Street 2nd Floor

NY, NY 10035

☎(917)

INSPECTOR GENERAL

80 Maiden Lane NY, NY 10005

☎(212)

RESTAURANT WORKER

SAFETY AND HEALTH

☎(212)

REVISED EDITION 2013

Published by the

New York City Department of Health and Mental Hygiene

Division of Environmental Health

125 Worth Street

New York, NY 10013

ii

N E W Y O R K C I T Y D E P A R T M E N T O F H E A L T H & M E N T A L H Y G I E N E

fo d P R O T E C T I O N T R A I N I N G M A N U A L

d P R O T E C T I O N T R A I N I N G M A N U A L

INTRODUCTION

INTRODUCTION

The New York City Department of Health and Mental Hygiene has the jurisdiction to regulate all matters affecting health in the city and to perform all those

functions and operations that relate to the health of the people of the city.

this certification may be needed at an establishment to have coverage dur- ing all shifts, vacations or illnesses.

The Food Protection Manual has been designed to assist participants of the course to better understand the principles of safe food handling. It serves as a reference for food ser- vice operators and it includes the necessary information to pass the final examination.

The Health Code

These are regulations that were formulated to allow the Department to effectively protect the health of the population. Among the rules embodied in the Health Code is Article 81 which regulates the oper- ations of food establishments for the purpose of preventing public health hazards.

Environmental Health Division

The Division of Environmental Health is the Commission within the Health Department that is concerned with public health and works to eliminate the incidence of injury and illness caused by environmental factors.

There are several Offices and Bureaus within this division. One of these is the Bureau of Food Safety and Community Sanitation that has the responsibility for con- ducting inspections of food service and food processing establishments. These inspections are performed by Public Health Sanitarians.

All Sanitarians have Department of Health and Mental Hygiene badges and identification cards which they must display whenever it is requested of them.

It is illegal to offer a Sanitarian any bribe, gratuity or reward for official misconduct; this is a crime

that can result in fines, and /or imprisonment, and the revocation of permits. Also, Sanitarians are not authorized to conduct any monetary transactions on behalf of the Department.

Inspector General

This is an office that exists within the Health Department with the responsibility of investigating any incidence of alleged corrupt activity. Investigations may be conducted as a result of complaints by employees of the Department or members of the public.

Health Academy

The Health Academy is an office within the Division of Environmental Health. One of its responsibilities is to provide training and certification courses for individuals from the public as mandated by the Health Code.

The Food Protection Course is one of the courses taught here. The Food Protection Course is required by the Health Code for supervisors of food service establishments and

The Food Protection Course in English, Spanish and Chinese is now also available

Register for Health Academy Classes

You may now register and pay online for courses offered at the Department of Health and Mental Hygiene’s Health Academy, includ- ing the Food Protection Course for restaurants. This new service allows you to avoid going to the Citywide Licensing Center to register for a course. You may also use the

How does it work?

Go to the registration web page, nyc.gov/healthacademy, select a course and date, pay the appropriate fee and receive confirmation.

You will be asked to provide some personal information before regis- tering. In most cases, you will be able to select from a list of course dates. If you don’t see a date that is convenient, check back as new course dates are added frequently.

N E W Y O R K C I T Y D E P A R T M E N T O F H E A L T H & M E N T A L H Y G I E N E |

|

1 |

|

|

|

fo d P R O T E C T I O N T R A I N I N G M A N U A L

d P R O T E C T I O N T R A I N I N G M A N U A L

QUICK REVIEW

1.All food service establishments must have a current and valid permit issued by the NYC Health Department.

TRUE FALSE

2.Health Inspectors have the right to inspect a food service or food processing establishment as long as it is in operation. Inspectors must be given access to all areas of establishment during an inspection. TRUE FALSE

3.Health Inspectors are authorized to collect permit fees and fines on behalf of the Department. TRUE FALSE

4.Health Inspectors must show their photo identification and badge to the person in charge of an establishment.

TRUE FALSE

5.According to the NYC Health Code, who is required to have a Food Protection Certificate? ________________________________.

INTRODUCTION TO FOOD SAFETY

What are Potentially Hazardous

Foods (PHF)?

The United States has one of the safest food safety systems in the world, yet millions of Americans still get sick each year from eating contami- nated foods; hundreds of thousands are hospitalized; and several thou- sand die. This means that there is still tremendous room for improve- ment in food safety standards.

Most

Sick food worker

Poor personal Hygiene/Bare hand contact

Improper holding temperatures

Improper cooling

Inadequate cooking and reheating

Cross contamination

Use of food from unknown source

What is

Any illness that is caused by food is called

|

|

This expression refers to those foods |

|

|

|

that provide suitable conditions for |

|

viruses, parasites, fungi etc. Injury |

rapid growth of microorganisms. |

||

and illness caused by foreign objects, |

These include foods that are high in |

||

dangerous chemicals and/or allergens |

protein like raw or cooked animal |

||

in food is also considered a food- |

products such as meats, poultry, |

||

borne illness. |

fish, shellfish (mollusks as well as |

||

Who is at Risk? |

crustaceans), milk and milk products |

||

(cheese, butter milk, heavy cream etc.,), |

|||

We are all at risk of getting a food |

|||

plant protein such as tofu, and |

|||

borne illness; however, the effects are |

|||

starches such as cooked rice, cooked |

|||

more severe for certain categories of |

|||

pasta, cooked beans and cooked |

|||

individuals: |

|||

vegetables like potatoes, cut melons, |

|||

Children whose immune system |

|||

cut leafy greens, cut tomatoes or |

|||

(human body’s defense system |

|||

mixtures of cut tomatoes, as well as |

|||

against diseases) is not fully devel- |

|||

oped yet. |

raw seed sprouts and garlic in oil. |

||

Elderly individuals because their |

Exceptions: Those foods that have a |

||

immune system is not robust any- |

low water activity (.85 or less) or those |

||

more and has weakened due to old |

|||

that are highly acidic with a pH of |

|||

age. |

|||

4.6 or below. |

|||

Pregnant women where the threat |

|||

eggs with shells intact. |

|||

is both to the mother and the fetus. |

|||

|

|||

Individuals with com- |

|

||

promised immune sys- |

|

|

|

|

Potentially Hazardous Foods |

||

tems e.g., Patients with |

|

||

AIDS, cancer or indi- |

|

|

|

viduals who are diabet- |

|

|

|

ics, etc. |

|

|

|

People on medication |

|

|

|

(antibiotics, immunosup- |

|

|

|

pressant, etc.). |

|

|

|

What is food? |

|

|

|

Food is any edible sub- |

|

|

|

stance, ice, beverage, or |

|

|

|

ingredient intended for use |

|

|

|

and used or sold for |

|

|

|

human consumption. |

|

|

|

|

|

||

2 |

|

N E W Y O R K C I T Y D E P A R T M E N T O F H E A L T H & M E N T A L H Y G I E N E |

|

|

|

fo d P R O T E C T I O N T R A I N I N G M A N U A L

d P R O T E C T I O N T R A I N I N G M A N U A L

What is |

necessary permits to operate. The use of |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||||||

Any food product that does not |

foods prepared at home or in an unli- |

|

212° |

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|||||||||

need additional heat treatment or |

censed establishment is prohibited. |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

washing is called |

|

|

|

|

|

|

165° |

|

|

|

|

|

|

||||

Extra care must be taken to ensure |

The Temperature Danger Zone? |

|

140° |

|

|

|

|

|

|

||||||||

the safety of these foods. |

|

Most microorganisms that cause |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Where do we purchase foods? |

foodborne illness typically grow best |

|

|

|

DANGER |

|

|

||||||||||

|

|

|

|

|

|

|

|

ZONE |

|

|

|||||||

|

|

between temperatures of 41°F and |

|

|

|

|

|

||||||||||

All foods must be purchased from |

|

|

|

|

|

|

|

|

|

|

|||||||

140°F. This is commonly referred to |

|

|

|

|

|

|

|

|

|

|

|||||||

approved sources. These are manu- |

|

|

|

41° |

|

|

|

|

|

|

|||||||

as the temperature danger zone. One |

|

|

|

|

|

|

|

|

|

||||||||

facturers and suppliers who comply |

|

32° |

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

with all the rules and regulations that |

of the basic and simplest ways to keep |

|

|

|

|

Temperature |

|

|

|

||||||||

food safe is by keeping it out of the |

|

|

|

|

Danger |

|

|

|

|||||||||

pertain to the production of their |

|

|

|

0° |

|

|

|

||||||||||

temperature danger zone. |

|

|

|

|

Zone |

|

|

|

|||||||||

product, including having the |

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

How do we store potentially |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

hazardous foods? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All foods must be kept free from |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

adulteration, spoilage, filth or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

other contamination in order to be |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

suitable for human consumption. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Potentially hazardous foods are of |

|

|

|

|

|

Thermocouple |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cold temperature |

|||||||

particular concern because they |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

Thermometer |

|

|

Thermometer |

|

|

|

|

|

|

reading calibration |

|||||

provide the conditions suitable for |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

the growth of microorganisms. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

These foods must be kept either hot or |

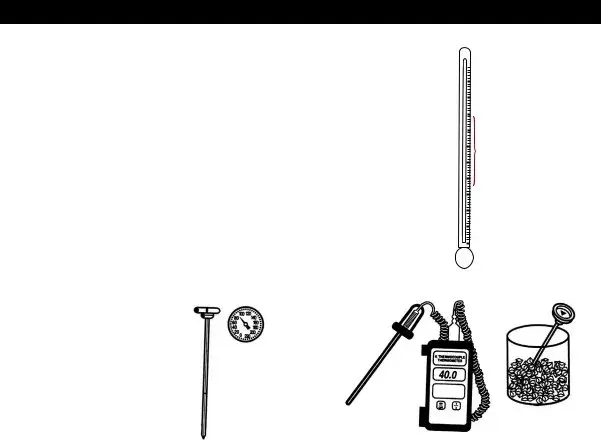

Also, it is available within the range |

in 50/50 solution of ice and water |

|||||||||||||||

cold to prevent microorganisms from |

of 0° to 220°F making it ideal for |

or boiling water, and hitting the |

|||||||||||||||

growing. Hot means 140°F or above |

measuring the required tempera- |

“reset” button will automatically |

|||||||||||||||

and cold means 41°F or below. The |

tures in a food establishment. |

calibrate the thermometer. |

|||||||||||||||

temperature range between 41°F and |

|

Another thermometer in use is |

stem thermometers may be calibrated |

||||||||||||||

140°F is known as the temperature |

the thermocouple which is very accu- |

by two methods: |

|||||||||||||||

danger zone. It is within this range |

rate but fairly expensive. Lastly, there is |

||||||||||||||||

that microorganisms are comfortable |

a thermometer called thermistor, |

||||||||||||||||

and will grow rapidly. At 41°F and |

which has a digital read out and is |

|

|

|

|

|

|

|

|

|

|

||||||

below, the temperature is cold |

commonly called "digital thermometer." |

||||||||||||||||

enough to retard or slow down the |

|

These thermometers are used by |

Bring water to a boil. |

||||||||||||||

growth of microorganisms, while |

inserting the probe into the thickest |

Place the thermometer probe (stem) |

|||||||||||||||

above 140°F most of the microor- |

part or the geometric center of the |

into the boiling water. Make sure |

|||||||||||||||

ganisms which cause foodborne ill- |

food item being measured. The stem |

that the thermometer probe does |

|||||||||||||||

ness begin to die. |

thermometer must remain in the food |

not touch the bottom or sides of |

|||||||||||||||

|

|

until the indicator stops moving before |

the pan. Wait until the indicator |

||||||||||||||

Thermometers |

stops moving, then record the |

||||||||||||||||

the reading is taken and must be re- |

|||||||||||||||||

|

|

||||||||||||||||

The only safe way to determine |

temperature. |

||||||||||||||||

calibrated periodically to assure accuracy. |

|||||||||||||||||

that potentially hazardous foods are |

If the temperature is 212°F, do |

||||||||||||||||

|

|

|

|

|

|||||||||||||

kept out of the temperature danger |

|

|

|

|

|

||||||||||||

Calibration |

|

|

nothing, the thermometer is accurate. |

||||||||||||||

|

|

|

|

|

|

|

|||||||||||

zone is by the use of thermometers. |

|

Thermometers must be calibrated |

(This is the temperature of boiling |

||||||||||||||

There are several different types of |

to ensure their accuracy. For thermo- |

water at sea level.) |

|||||||||||||||

thermometers. The |

couple thermometers, follow the |

If the temperature is not 212°F, |

|||||||||||||||

the most popular type. It is fairly |

instructions provided by the manu- |

rotate the |

|||||||||||||||

inexpensive, easy to use, accurate to |

facturer. For some thermistor ther- |

a wrench or other tool until the |

|||||||||||||||

+ or – 2°F and easy to |

mometers, placing the thermometer |

indicator is at 212°F. |

|||||||||||||||

N E W Y O R K C I T Y D E P A R T M E N T O F H E A L T H & M E N T A L H Y G I E N E |

|

3 |

|

|

|

fo d P R O T E C T I O N T R A I N I N G M A N U A L

d P R O T E C T I O N T R A I N I N G M A N U A L

Fill a container with ice and water to |

make a 50/50 ice water slush. |

Stir the slush. |

RECEIVING FOODS

Place the thermometer probe so |

that it is completely submerged in |

the |

not to touch the sides or the bot- |

tom. Wait until the indicator nee- |

dle stops moving, then record the |

temperature. |

If the temperature is 32°F, do |

nothing, the thermometer is |

accurate. (A 50/50 ice water slush |

will always have a temperature of |

32°F at |

ture is not 32°F, rotate the hex- |

adjusting nut until the indicator |

needle is at 32°F. |

How to use a Thermometer

The following describes the proper method of using thermometers:

Sanitize the probe by the use of |

alcohol wipes. This is a fairly safe |

and common practice. Other |

methods such as immersion in |

water with a temperature of 170°F |

for 30 seconds or in a chemical |

sanitizing solution of 50 PPM for |

at least one minute, or swabbing |

with a chlorine sanitizing solution |

of 100 PPM are also acceptable. |

Measure the internal product |

temperature by inserting the probe |

into the thickest part or the center |

of the product. It is recommend- |

ed that the temperature readings |

be taken at several points. |

Whenever using a |

thermometer, ensure that the |

entire sensing portion – from the |

tip of the probe to the indenta- |

tion on the stem, is inserted in to |

the food product. |

The first opportunity one has to ensure that food is safe is at the point of receiving. At this point care

must be taken to ensure that all products come from approved sources and/or reliable and rep- utable suppliers. Incoming supplies must be received at a time when it is convenient to inspect them and place them into storage promptly. There are various qualities and con- ditions one should look for in dif- ferent food items.

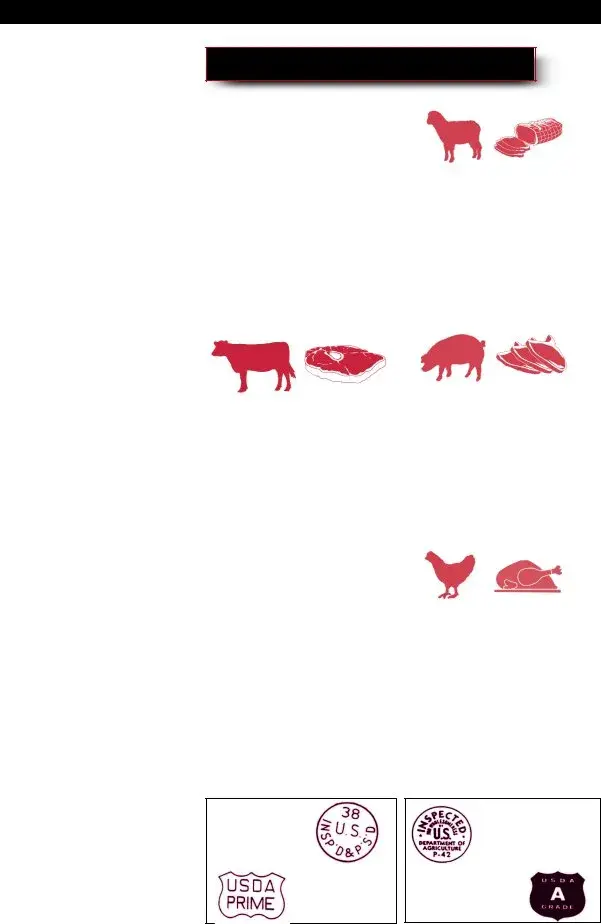

Beef

Incoming supplies of beef can be received either fresh or frozen. Fresh beef should be at 41°F or below while frozen beef should be at 0°F or below. Beef should be bright to dark red in color with no objection- able odor. To ensure that the supply is from an approved source, look for the United States Department of Agriculture inspection stamp. This can be found on the sides of the beef carcass or on the box when receiving portions of the carcass. This inspection is mandatory and the stamp indicates that the meat is sanitary, wholesome and fit for human consumption. Also found may be a grade stamp which attests to the quality of the meat and will certainly have an impact on its price. The inspection stamp is the more important of the two stamps.

Lamb

Lamb, like beef, may have an inspection stamp as well as a grade stamp. When fresh, it is light red in color and has no objectionable odor and the flesh is firm and elastic. Fresh lamb is received at 41°F and frozen at or below 0°F. (See stamps below)

Pork

Pork is also subject to USDA inspection. The flesh is light colored while the fat is white. A good way to check for spoilage is to insert a knife into the flesh all the way to the bone and check the blade for any off odors. (See stamps below)

Chicken and Poultry

Chicken and poultry are subject to USDA inspection which must be verified by the inspection stamp. (See stamps below) These must be received either fresh at 41°F and below or frozen at 0°F or less, as they are naturally contaminated with the

Wait for roughly 15 seconds or |

until the reading is steady before |

recording it. |

Clean and sanitize the thermometer |

for later use. |

USDA Meat |

USDA Poultry |

Inspection Stamp |

Inspection Stamp |

|

USDA Poultry |

USDA Meat |

|

Grade Stamp |

Grade Stamp |

|

|

4 |

|

N E W Y O R K C I T Y D E P A R T M E N T O F H E A L T H & M E N T A L H Y G I E N E |

|

|

|

fo d P R O T E C T I O N T R A I N I N G M A N U A L

d P R O T E C T I O N T R A I N I N G M A N U A L

Fresh fish

There is no inspection for fresh fish other than what can be done by sight and touch and one’s sense of smell. This makes it more impor- tant to purchase supplies from rep- utable and reliable suppliers. Fresh fish must be received cold and on ice, 41°F or less, with no objection- able odor. The eyes must be clear and bulging, the gills bright red and the flesh firm and elastic. Fish that is spoiling will have a fishy odor; the eyes cloudy, red rimmed and sunken; the gills grey or greenish; the flesh will pit on pressure and can easily be pulled away from the bones; the scales are loose.

Smoked fish

Smoked fish provide ideal condi- tions for the growth of Clostridium botulinum spores if left at room temperature. Therefore, upon receipt, all smoked fish must be stored at 38°F or below.

It is important to adhere to the temperature requirements stated on the label.

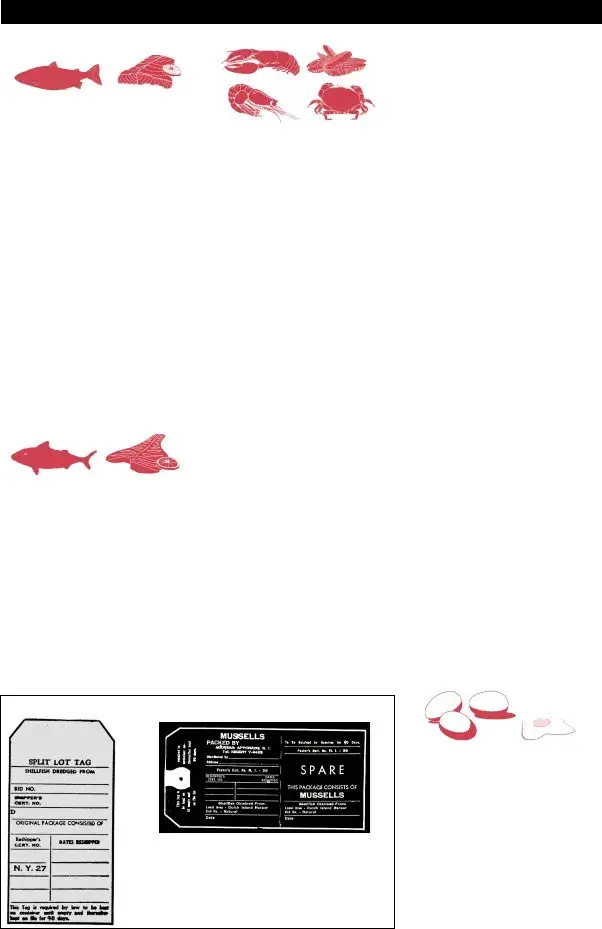

Shellfish

Shellfish is the term used to describe clams, mussels, and oysters. These belong to the family of mol- lusks. They are filter feeders, that is, they absorb water from their envi- ronment, filter out whatever nutri- ents are there and then expel the water. Feeding in this manner causes them to absorb and accumulate harmful microorganisms from pollut- ed waters. Since the whole shellfish is eaten either raw or partially cooked, it is critical to ensure that they are harvested from safe waters. It is important to buy shellfish from reputable suppliers who can provide the shipper’s tags which identify the source of the shellfish. These tags supply the following information:

The name of the product

The name of the original shipper

The address of the original shipper

The interstate certificate number of the original shipper

The location of the shellfish har- vesting area.

When purchasing small amounts from a retailer, a tag must be pro- vided. This is a

has all the information that is on the original tag.

The shellfish tag is required to be kept together with the product, then whenever the product is used up, it must be kept for 90 days in order of delivery. The virus Hepatitis A is associated with shellfish.

Check if the shellfish is alive. An opened shell may be an indication of dead shellfish. Gently tap on the shell, if the shell closes then it is alive otherwise it’s dead and should be discarded. Both alive as well as shucked shellfish (shellfish that has been removed from its shell) must only be accepted if delivered at a temperature of 41°F or below. Following conditions would auto- matically be grounds for rejection:

Slimy, sticky or dry texture

Strong fishy odor

Broken shells

Other Shellfish

Lobsters, crabs and shrimps belong to the family of crustaceans. Fresh lobsters and crabs must be alive at the time of delivery. As with other seafood, a strong fishy odor is an indication of spoilage. The shell of the shrimp must be intact and firm- ly attached. All processed crustacean must be delivered at 41°F or below.

Split Lot Tag |

Shellfish Tag |

|

It is strongly recommended that the invoices be kept with the tags to aid in tracing the lot’s history.

Eggs

Eggs produced outside of New York State are inspected by the U.S. Department of Agriculture while those produced within the State are inspected by the New York State Department of Agriculture and Markets. In either case, inspected eggs will be identified by a stamp on the carton. Eggs have long been

N E W Y O R K C I T Y D E P A R T M E N T O F H E A L T H & M E N T A L H Y G I E N E |

|

5 |

|

|

|

fo d P R O T E C T I O N T R A I N I N G M A N U A L

d P R O T E C T I O N T R A I N I N G M A N U A L

associated with the

Eggs should be bought from sup- pliers who deliver them in refriger- ated trucks and upon receipt, these eggs must be kept refrigerated at an ambient temperature of 45°F until they are used.

pasteurized milk and milk products must not exceed 45 days from date of ultra pasteurization.

Upon receipt, these products must be checked to ensure that they are well within the expiration period and that they are at 41°F or below. This temperature must be main- tained until the product is used up.

watermelons, cantaloupes, honey dews and all varieties of melons, oranges, etc. Only potable running water should be used to thoroughly wash these produce, and the use of produce scrubbing brushes is strongly recommended.

Egg Cartons Stamps

Pasteurized Eggs

Pasteurization is a method of heating foods to destroy harmful microorganisms. Pasteurized eggs come in many forms: intact shell eggs, liquid eggs, frozen eggs, or in pow- dered form. Even though these have been pasteurized, they still require refrigeration to slow down growth of spoilage microorganisms to extend the shelf life. Only the powdered pasteurized eggs may be held at room temperature.

Milk and Milk Products

Only accept Grade A pasteurized milk and milk products. Harmful pathogens such as Listeria monocy- togenes, E.coli 0157:H7 and Salmonella spp. are commonly asso- ciated with

The expiration date on pasteur- ized milk and milk products must not exceed nine calendar days from date of pasteurization, while ultra

|

|

|

Canned Goods |

|

||

|

|

|

It is a simple task to inspect |

|||

|

|

|

canned goods and remove from cir- |

|||

|

|

|

culation those cans that can cause |

|||

Fresh Fruits and Vegetables |

|

foodborne illness. The first step is |

||||

|

|

|

|

|||

The acceptable condition of fruits |

to ensure that home canned foods |

|||||

are not used in a food service estab- |

||||||

and vegetables vary from one item |

|

|||||

|

lishment. All canned foods must be |

|||||

to another. As a general rule of thumb, |

||||||

commercially processed. A good can |

||||||

only accept those that do not show |

||||||

is free from rust and dents, properly |

||||||

any signs of spoilage. Reject any |

|

|||||

|

sealed and labeled and slightly con- |

|||||

produce that shows signs of decay, |

|

|||||

|

cave at both ends. |

|

||||

mold, mushiness, discoloration, |

|

|

||||

|

|

|

|

|||

wilting, and bad odors. |

|

A can with a dent on any of the |

||||

A recent study done by the center |

|

|||||

|

three seams (top, bottom or side) |

|||||

for Science in the Public Interest |

|

|||||

|

must be removed from circulation. |

|||||

(CSPI) found that contaminated fruits |

||||||

The same requirement is true for |

||||||

and vegetables are causing more food- |

||||||

severely rusted, severely dented, leak- |

||||||

borne illness among Americans than |

||||||

ing and cans with swollen ends. Bad |

||||||

raw chicken and eggs combined. |

|

|||||

|

cans may be rejected at delivery or seg- |

|||||

Most fresh produce may become |

|

|||||

|

regated and clearly labeled for return |

|||||

contaminated with Salmonella and |

|

|||||

|

to the supplier. |

|

||||

E.coli 0157:H7 due to the |

|

|

||||

|

|

|

|

|||

use of manure fertilizer |

|

|

|

|

||

|

|

|

|

|

|

|

(more common in South |

|

|

|

|

|

|

and Central America, which |

|

|

|

|

|

|

is a major source of fresh |

|

|

|

|

|

|

produce to the United |

|

|

|

|

|

|

States). |

|

|

|

|

|

|

Fresh produce must be |

|

|

|

|

|

|

thoroughly washed prior to |

|

|

|

|

|

|

being served raw. This |

|

|

|

|

|

|

includes all kinds of fruits |

|

|

|

|

|

|

and vegetables including |

|

swollen |

severe dents |

slight rust |

||

produce that has a hard |

|

critical |

major |

minor |

||

rind that is typically not |

|

|

|

|

|

|

|

|

|

|

|

||

consumed, for example, |

|

|

|

|

||

6 |

|

N E W Y O R K C I T Y D E P A R T M E N T O F H E A L T H & M E N T A L H Y G I E N E |

|

|

|

fo d P R O T E C T I O N T R A I N I N G M A N U A L

d P R O T E C T I O N T R A I N I N G M A N U A L

Modified Atmosphere

Packaged Foods

Various food items are packaged under special conditions to prolong their shelf life. These conditions include the following:

Food is placed in a package and all the air is withdrawn: vacuum packaging.

Food is placed in a package, all the air is withdrawn and gases are added to preserve the contents – modified atmosphere packaging.

Food is placed in a package, all the air is withdrawn and the food

is cooked in the package: sous vide packaging.

Because of the absence of air, foods packaged in this manner provide ideal conditions for the growth of the clostridium botulinum

These products must be provided by approved sources and care taken to preserve the packaging during handling and when taking the tem- perature.

Food establishments interested in making “modified atmosphere pack- aged foods” must first obtain per- mission from NYC DOHMH.

For more information , please see Page 54.

Dry Foods

Dry foods such as grains, peas,

beans, flour and sugar are to be dry at the time of receiving. Moisture will cause growth of molds and the deterioration of these products. Broken and defective packages will indicate contamination; as will the evidence of rodent teeth marks.

Whenever these products are removed from their original con- tainers, they must be stored in tightly covered,

Refrigerated and Frozen

Processed Foods

For convenience as well as cutting down on costs, there has been a greater shift towards using prepared pre- packaged refrigerated or frozen foods. These routinely include deli and luncheon meats, refrigerated or frozen entrees, etc. Care should be taken when receiving these products to ensure quality as well as safety. Following are some guidelines:

Ensure that refrigerated foods are delivered at 41°F or below. (Except, as noted previously, smoked fish must be received at 38° F or lower.)

Ensure that frozen foods are delivered at 0°F or lower.

All packaging must be intact.

Any frozen food packaging that shows signs of thawing and refreezing should be rejected. Signs include liquid or frozen liquids on the outside packaging, formation of ice crystals on the packaging or on the product, and water stains.

QUICK REVIEW

1.The term "potentially hazardous food" refers to foods which do not support rapid growth of microorganisms. TRUE FALSE

2.Home canned food products are allowed in commercial food establishments. TRUE FALSE

3.The Temperature Danger Zone is between 41°F and 140°F.

TRUE FALSE

4.Within the Temperature Danger Zone, most harmful microorganisms reproduce rapidly. TRUE FALSE

5.Shellfish tags must be filed in order of delivery date and kept for a period of _______ days.

6.Fresh shell eggs must be refrigerated at an ambient temperature of: ______°F.

7.Foods in Modified Atmosphere Packages provide ideal conditions for the growth of: _______

8.The recommended range of

9.Meat inspected by the U.S. Dept. of Agriculture must have a/an:

____________ stamp.

10.Chicken and other poultry are most likely to be contaminated with: _______

11.Smoked fish provide ideal conditions for the growth of Botulinum spores. Therefore, this product must be stored at: ______°F

12.Safe temperatures for holding potentially hazardous foods are: ______°F or below and ______°F or above

13.What are the four types of defective canned products that must be removed from circulation? ______, ______, _____, _____

14.Which of the following is an indication that fish is not fresh?:

clear eyes fishy odor firm flesh

N E W Y O R K C I T Y D E P A R T M E N T O F H E A L T H & M E N T A L H Y G I E N E |

|

7 |

|

|

|

fo d P R O T E C T I O N T R A I N I N G M A N U A L

d P R O T E C T I O N T R A I N I N G M A N U A L

STORAGE OF FOOD

fter receiving the foods proper |

Storage Containers |

||

Aly, they must be immediately |

It is always best to store food in |

||

their original packaging; however, |

|||

moved to appropriate storage areas. |

|||

The most common types of food |

when it is removed to another con- |

||

storage include: |

tainer, take extra care to avoid cont- |

||

Refrigeration storage |

amination. Only use food containers |

||

that are clean, |

|||

Freezer storage |

|||

are made from |

|||

Dry storage |

|||

intended for such use. Containers |

|||

Storage in Ice |

|||

made from metal may react with |

|||

|

|||

We will discuss each of these |

certain type of high acid foods such |

||

individually; however, certain |

as sauerkraut, citrus juices, tomato |

||

aspects are common for all types of |

sauce, etc. Plastic |

||

storage and are described below. |

tainers are the best choice for these |

||

FIFO |

types of foods. Containers made of |

||

copper, brass, tin and galvanized metal |

|||

An important aspect of food stor- |

|||

should not be used. The use of such |

|||

age is to be able to use food products |

|||

products is prohibited. |

|||

before their |

|||

|

|

||

date. In this regard, stock rotation is |

|||

very important. The common sense |

store cooked foods is also a source |

||

approach of First in First out (FIFO) |

of contamination. Lining containers |

||

method of stock rotation prevents |

with newspapers, menus or other |

||

waste of food products and ensures |

publication before placing foods is |

||

quality. The first step in implement- |

also prohibited as chemical dyes from |

||

ing the FIFO method of stock rota- |

these can easily leach into foods. |

||

tion is to date products. Marking the |

Storage Areas |

||

products with a date allows food |

|||

Foods should only be stored in |

|||

workers to know which product was |

|||

designated areas. Storing foods in |

|||

received first. This way, the older stock |

|||

passageways, rest rooms, garbage |

|||

is moved to the front, and the newly |

|||

areas, utility rooms, etc. would sub- |

|||

received stock is placed in the back. |

|||

ject these to contamination. Raw |

|||

|

|||

|

|

foods must always be stored |

|

Cross Contamination |

|

below and away from cooked |

|

When harmful microorganisms are |

|

foods to avoid cross contami- |

|

transferred from one food item to |

|

nation. |

|

another, typically, from raw foods to |

|

Refrigerated Storage |

|

cooked or ready to eat foods, it is |

|

||

|

This type of storage is typi- |

||

termed cross contamination. This |

|

||

|

cally used for holding potential- |

||

expression also applies in any situa- |

|

||

tion where contamination from one |

|

ly hazardous foods as well as |

|

object crosses over to another. Cross |

|

perishable foods for short peri- |

|

contamination may also occur between |

|

ods of |

|

two raw products, for instance, |

|

few days. |

|

poultry juices falling on raw beef |

|

An adequate number of effi- |

|

will contaminate it with Salmonella, |

|

||

|

cient refrigerated units are |

||

which is typically only associated |

|

||

|

required to store potentially |

||

with poultry and raw eggs. |

|

||

|

|

||

|

|

|

|

hazardous cold foods. By keeping cold foods cold, the microorganisms that are found naturally on these foods are kept to a minimum. Cold

temperature does not kill microor- ganisms, however, it slows down their growth.

Fresh meat, poultry and other potentially hazardous foods must be stored at 41°F or below, while frozen foods must be stored at 0°F or below. For foods to be maintained at these temperatures, refrigerators and freezers must be operating at tem- peratures lower than 41°F and 0°F., respectively. Thermometers placed in the warmest part of a refrigerated unit are necessary to monitor the temperature of each unit.

The rule of storage, First In First Out (FIFO) ensures that older deliveries are used up before newer ones. In practicing FIFO, the very first step would be to date all prod- ucts as they are received. The next step is to store the newer products behind the older ones.

The following rules are important in making sure that foods are safe during refrigerated storage:

Store cooked foods above raw foods to avoid

Keep cooked food items covered unless they are in the process of cooling, in which case they must be covered after being cooled to 41°F.

Avoid placing large pots of hot foods in a refrigerator. This will cause the temperature of the refrigerator to rise and other foods will be out of temperature.

8 |

|

N E W Y O R K C I T Y D E P A R T M E N T O F H E A L T H & M E N T A L H Y G I E N E |

|

|

|