We have applied the hard work of our best programmers to develop the PDF editor you may want to take advantage of. Our app will enable you to create the njmvc quarterly vehicle inspection report pdf document with no trouble and don’t waste time. Everything you need to do is keep up with these straightforward steps.

Step 1: Click the "Get Form Here" button.

Step 2: After you've accessed the editing page njmvc quarterly vehicle inspection report pdf, you should be able to discover each of the options readily available for the file in the upper menu.

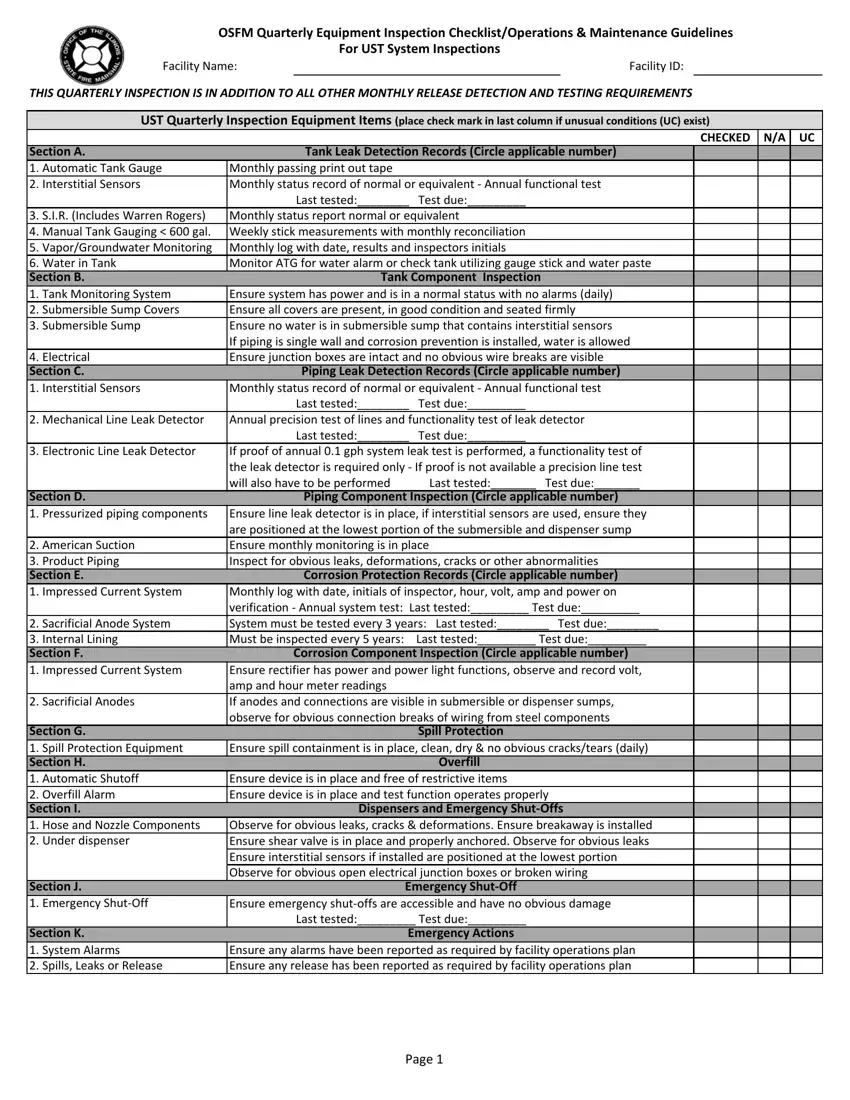

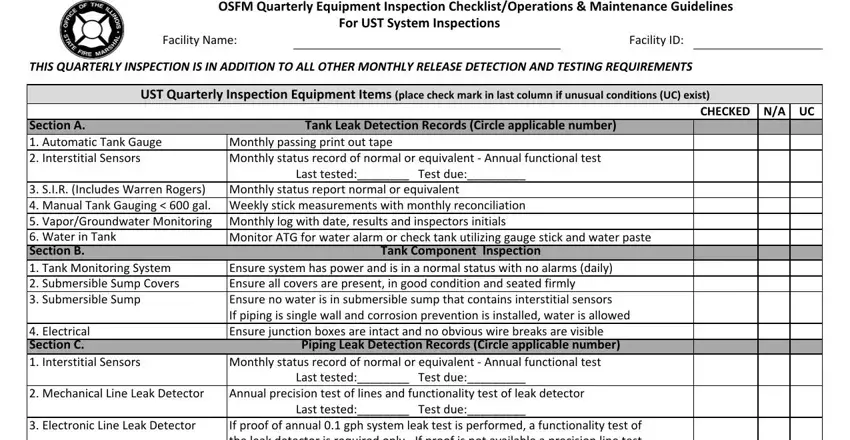

Complete the njmvc quarterly vehicle inspection report pdf PDF by typing in the data required for each individual area.

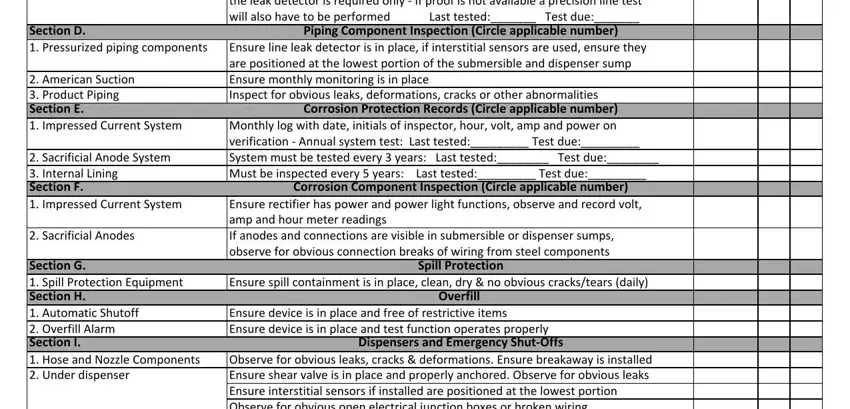

In the segment Electronic Line Leak Detector, Section D Pressurized piping, American Suction Product Piping, Sacrificial Anode System, Sacrificial Anodes, Section G Spill Protection, If proof of annual gph system, Piping Component Inspection Circle, Ensure line leak detector is in, Corrosion Protection Records, Corrosion Component Inspection, Ensure rectifier has power and, Spill Protection, Ensure spill containment is in, and Ensure device is in place and free enter the data which the system demands you to do.

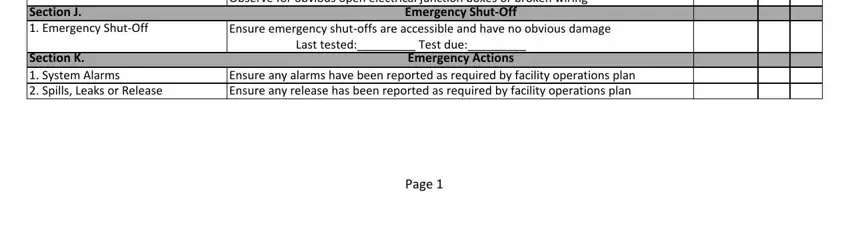

It is vital to record particular particulars inside the area Section J Emergency ShutOff, Section K System Alarms Spills, Observe for obvious leaks cracks, Emergency ShutOff, Ensure emergency shutoffs are, Last tested Test due, Emergency Actions, Ensure any alarms have been, and Page.

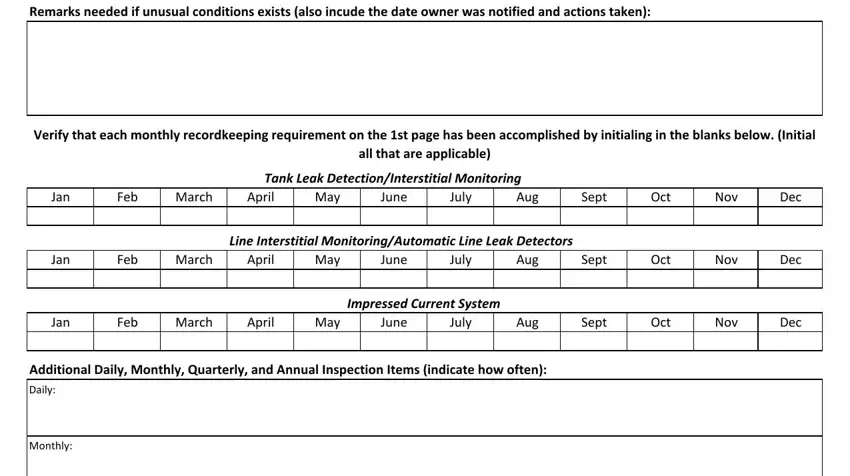

The Remarks needed if unusual, Verify that each monthly, Jan, Feb, March, Jan, Feb, March, Tank Leak DetectionInterstitial, May, July, April, Aug, Line Interstitial, and April area is the place to insert the rights and obligations of both parties.

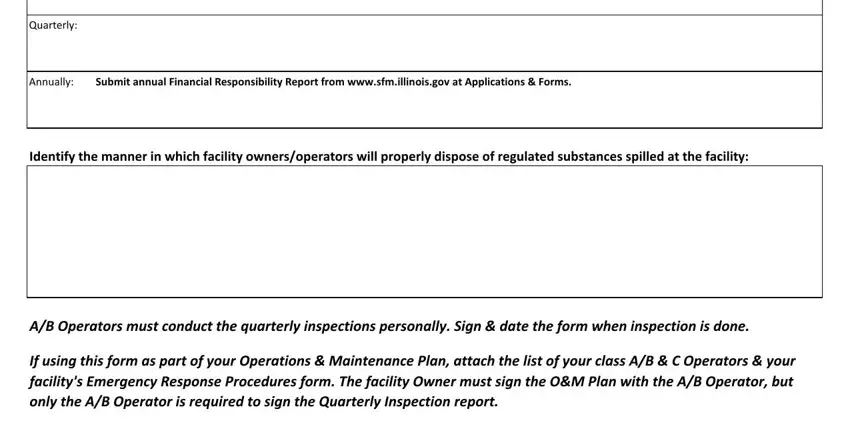

Look at the sections Quarterly, Annually, Submit annual Financial, Identify the manner in which, AB Operators must conduct the, and If using this form as part of your and thereafter complete them.

Step 3: As you click the Done button, your ready form can be exported to any of your gadgets or to electronic mail provided by you.

Step 4: Get a duplicate of each form. It will save you time and allow you to stay clear of challenges later on. Keep in mind, your data isn't revealed or analyzed by us.